Story

Introduction:

Every workbench should have at least one power supply.

Every workbench should have at least one power supply.

When you’re experimenting with electronics and microcontrollers a good power supply can be an essential piece of equipment. While you can certainly make do with USB power bricks and “battery eliminators” nothing beats having a dedicated power supply with plenty of voltage selection and current capability.

An ideal workbench power supply should have both 5-volt and 12-volt outputs, with 3.3-volts being a nice option as well. It should be capable of providing several amperes of current for each voltage.

You can buy bench power supplies of course, but they are not inexpensive. As the current capability and number of output voltages go up so does the price.

While a commercial bench power supply is certainly a worthwhile investment there is a cheaper solution that you might want to consider. Adapt an old computer power supply to use on your workbench.

Computer power supplies have all the voltages you’ll need and some very impressive current capabilities. And, thanks to mass production, they are cheap when compared to dedicated bench power supplies.

In fact, if you have access to an old computer that is on its way to the junk heap you can rescue its power supply and put together a nice bench power supply for just a few dollars.

That’s what I did actually – an old Windows desktop computer has now become a useful addition to my workshop.

Thank You NextPCB:

This project is successfully completed because of the help and support from NextPCB. NextPCB is one of the most experienced PCB manufacturers in Global, has specialized in the PCB and assembly industry for over 15 years. Not only could NextPCB provide the most innovative printed circuit boards and assembly technologies in the highest quality standards, the fastest delivery turnaround as fast as 24 hours.

Guys if you have a PCB project, please visit their website and get exciting discounts and coupons.

Only 0$ for 5-10pcs PCB Prototypes:Nextpcb.com/pcbprototype

4-layer PCB price reduction up to 40%: Nextpcb.com/4-layer-pcb

Register and get $100 from NextPCB: Nextpcb.com/coupon

Supplies:

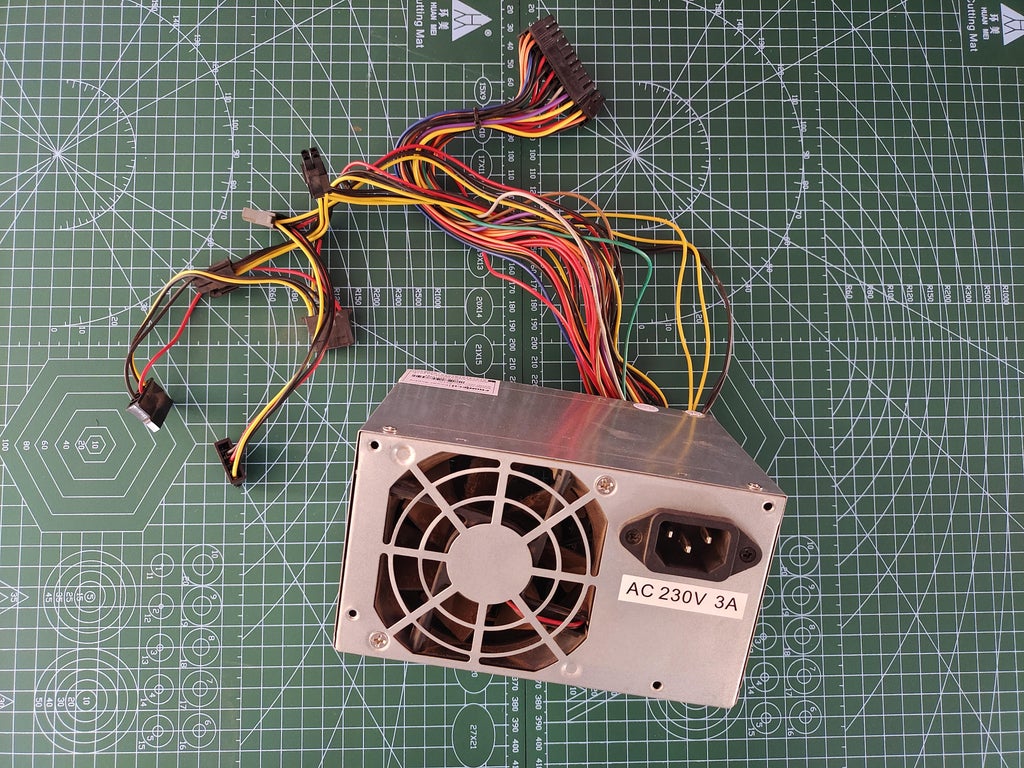

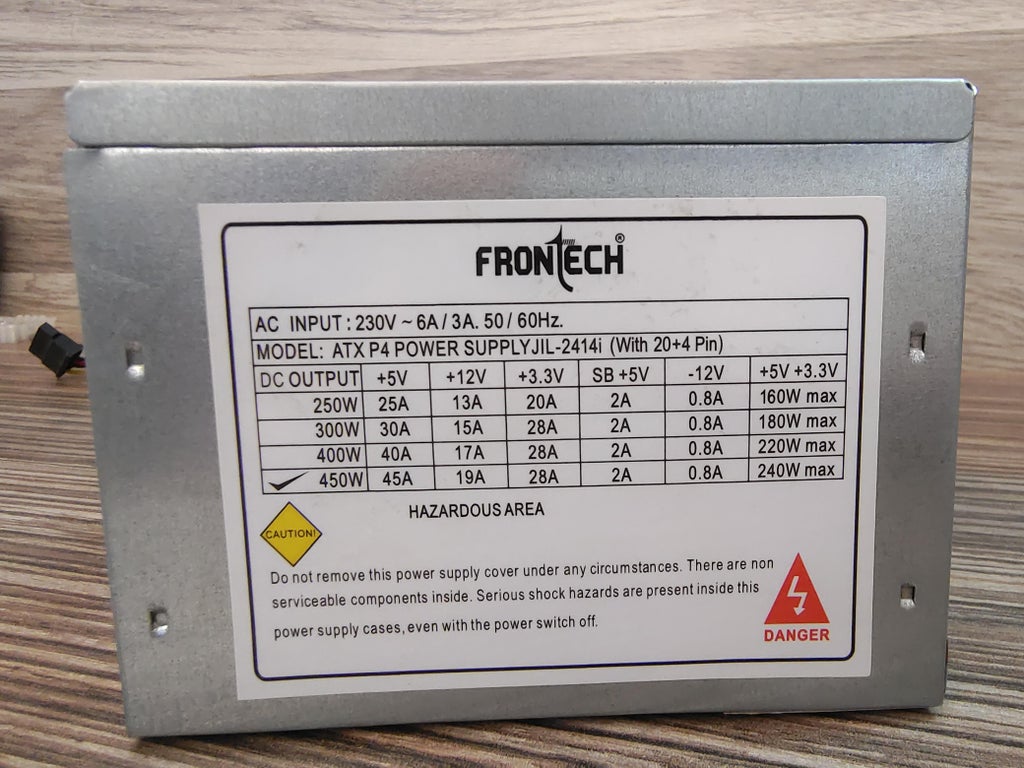

1 x AXT Power Supply

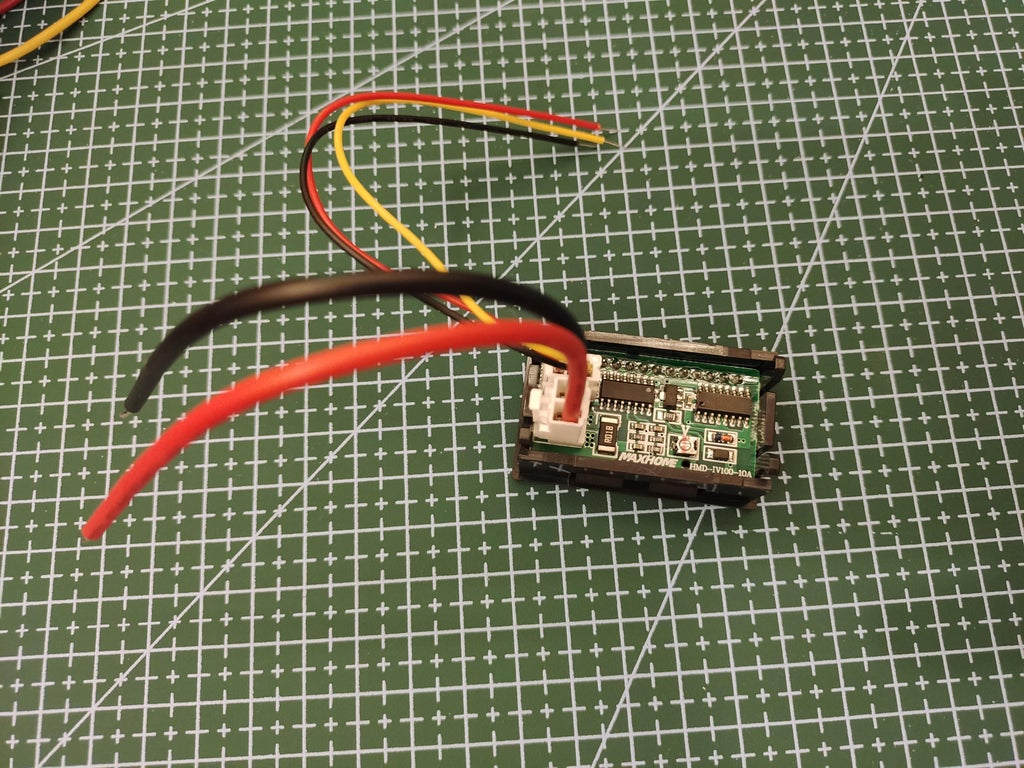

1 x DC Volt/Amp Digital Meter

15 x Female Banana Connectors (7-0Black, 8-Red)

1 x 50W 8 Ohm Load Resistor

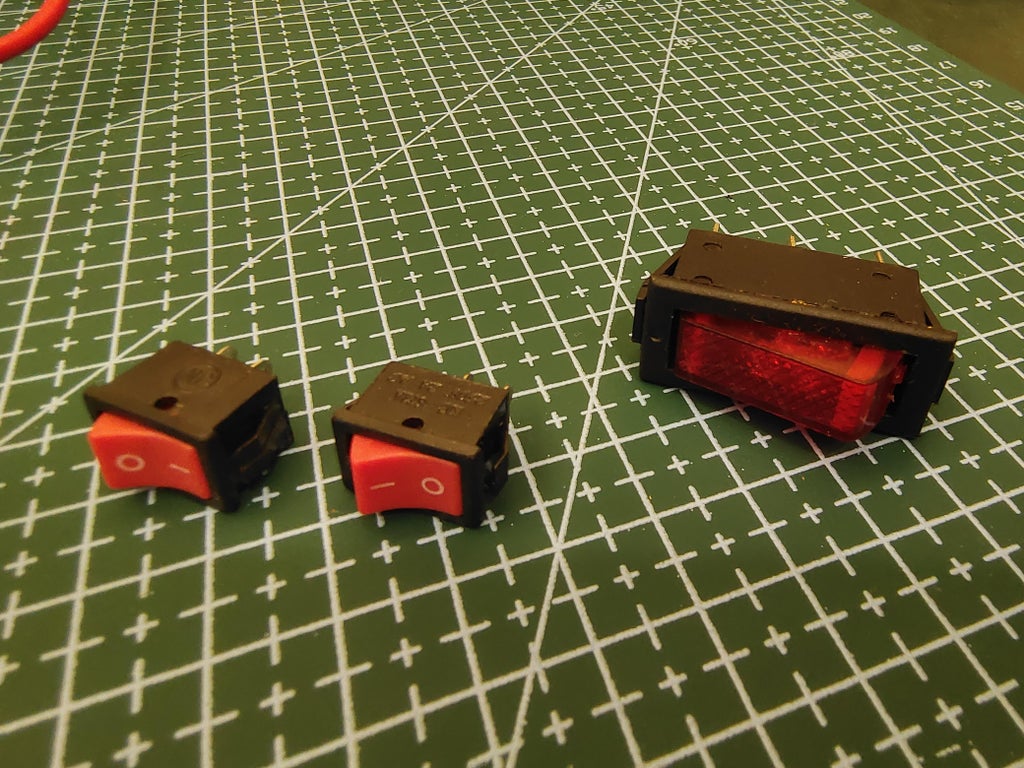

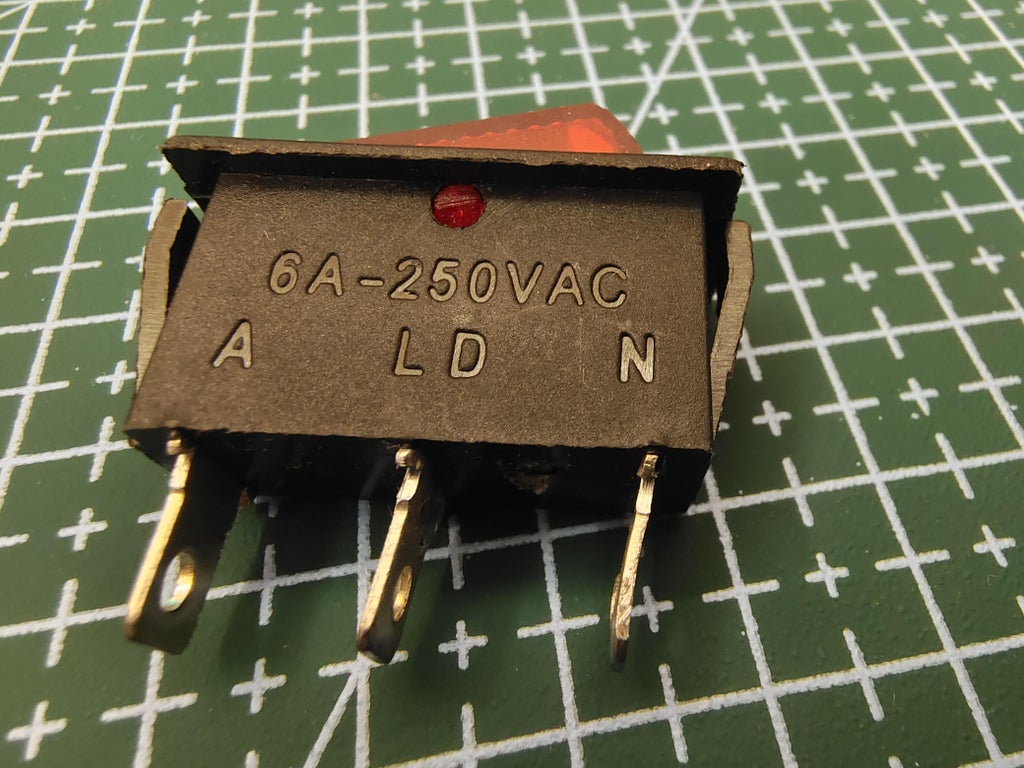

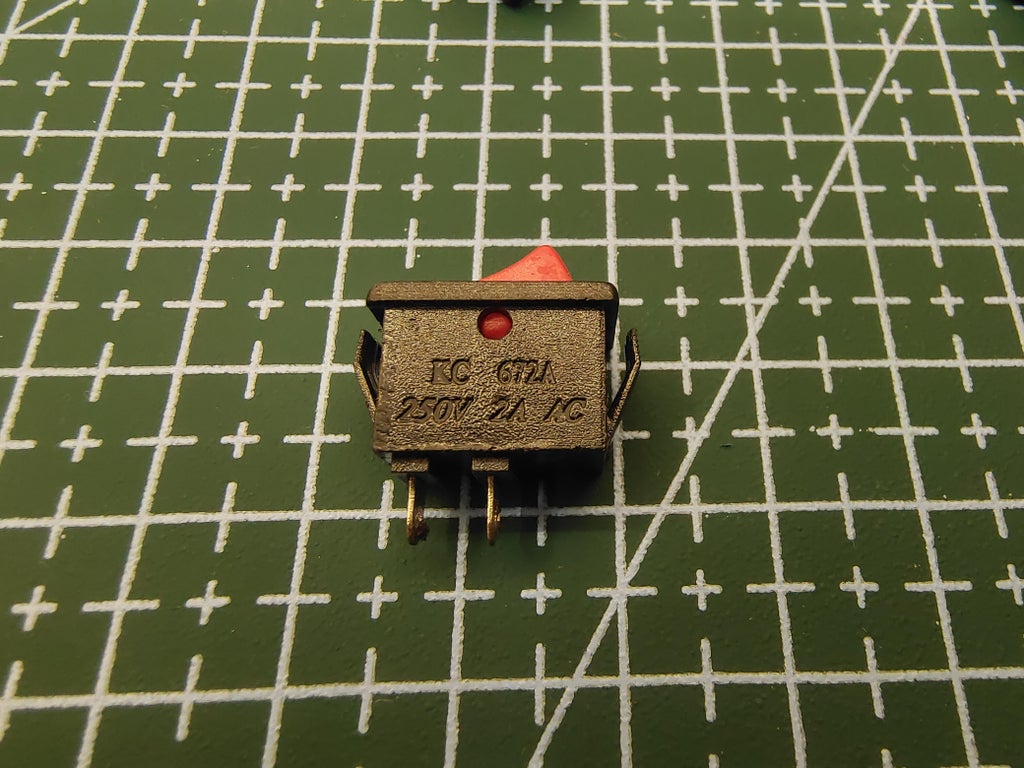

1 x AC Switch

2 x Mini DC Switch

1 x LED

1 x 10KOhm Resistor

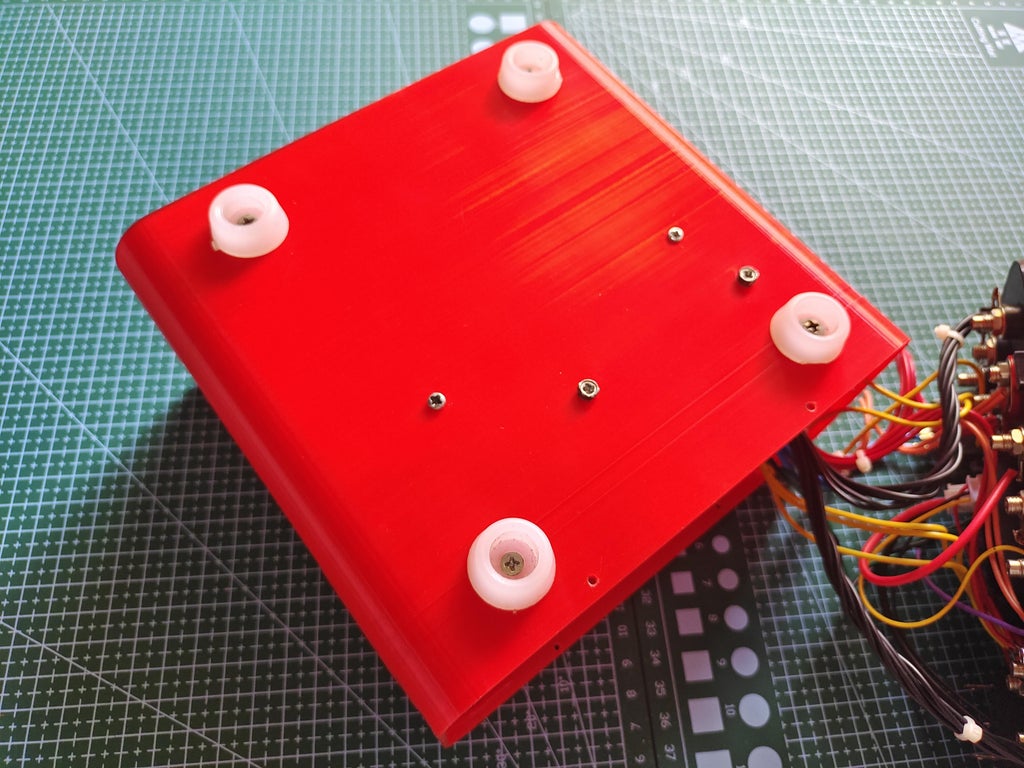

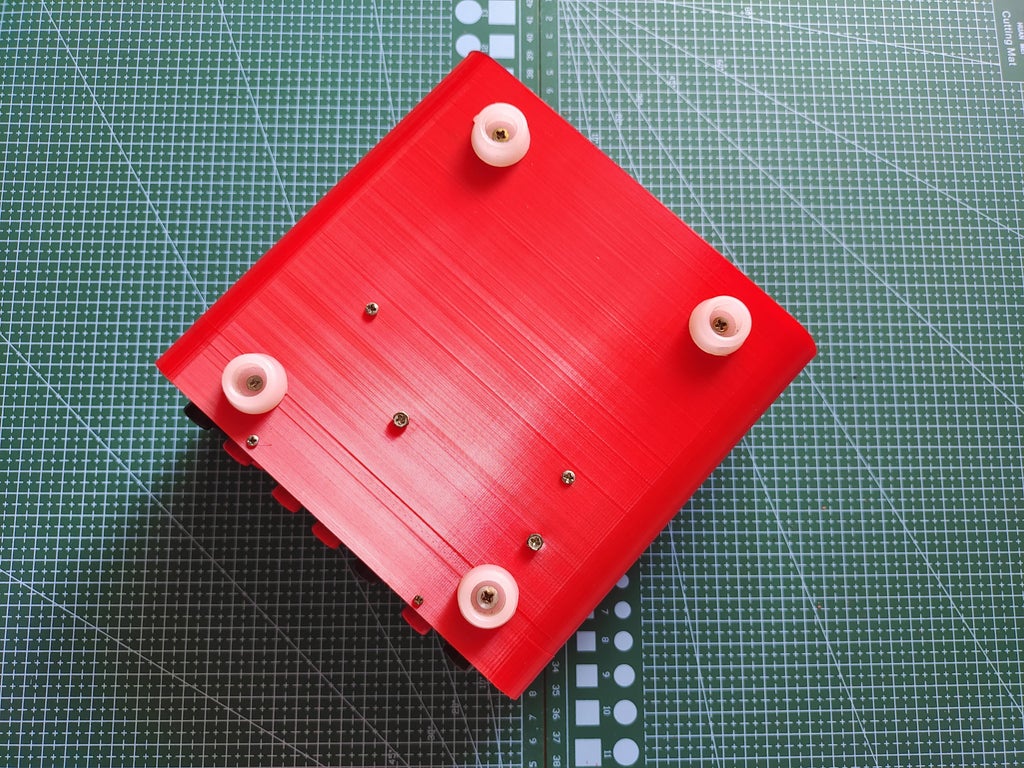

4 x Rubber Foot

Few Male Banana Connectors

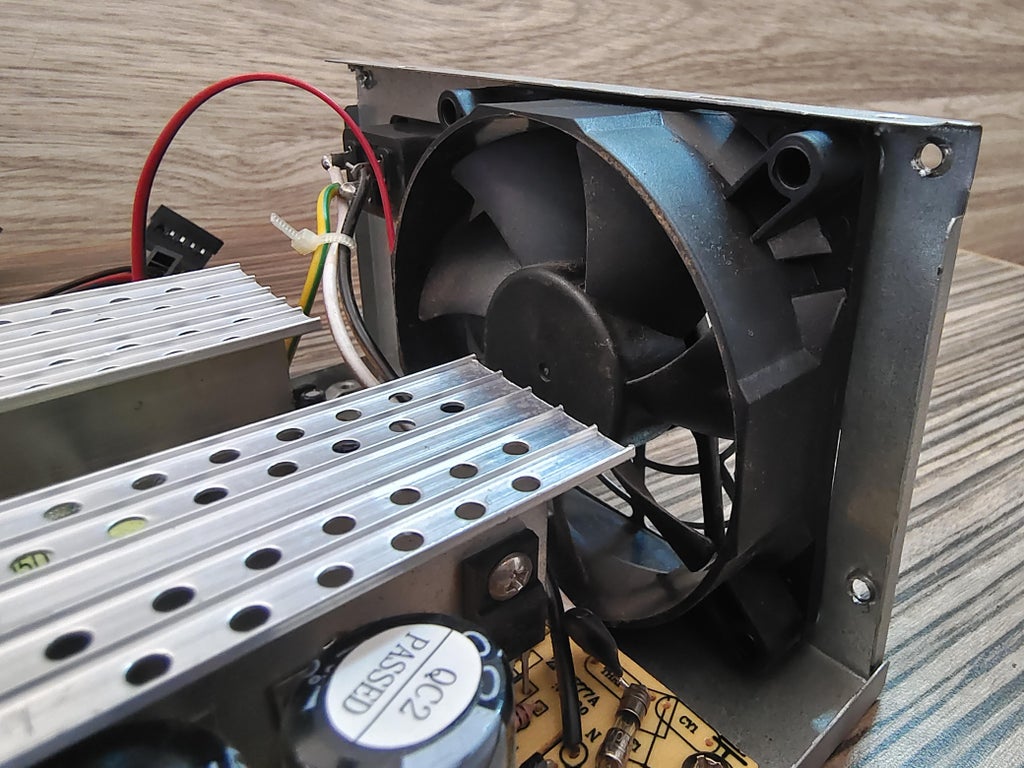

Step 1: Cleaning the Old Power Supply:

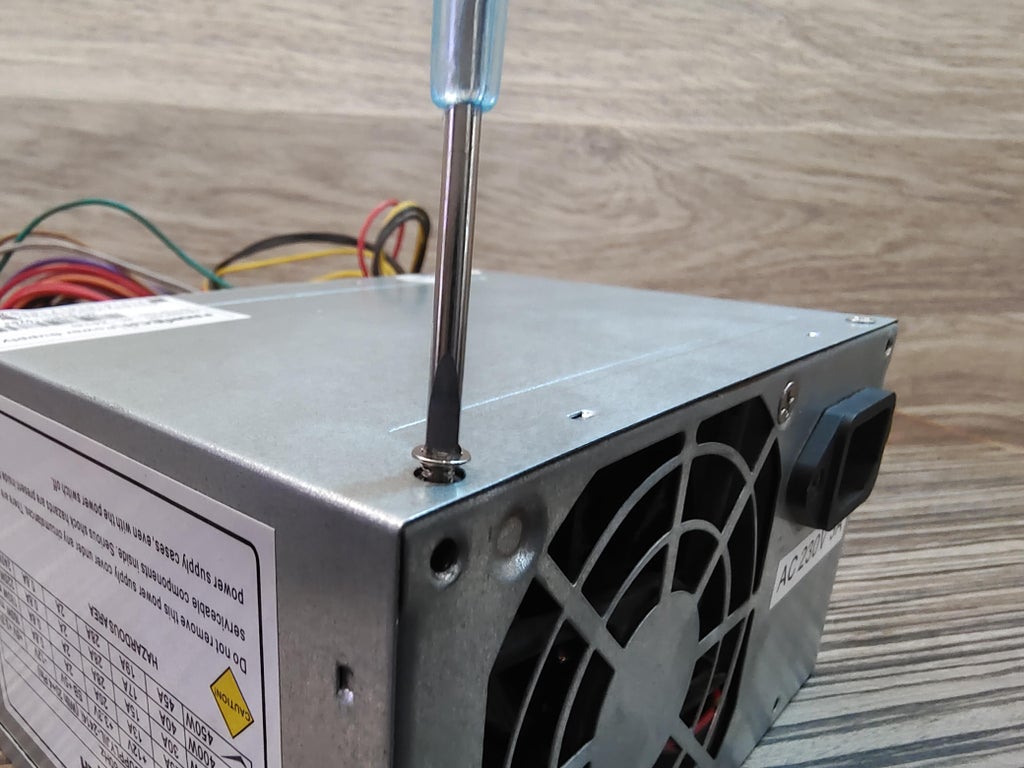

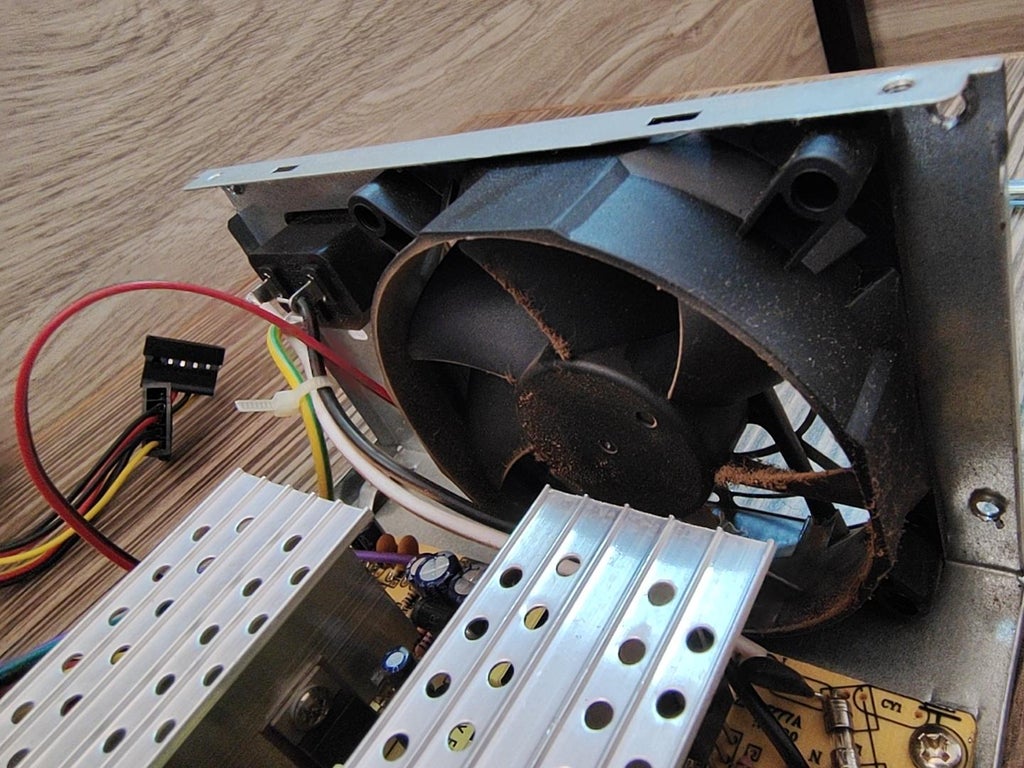

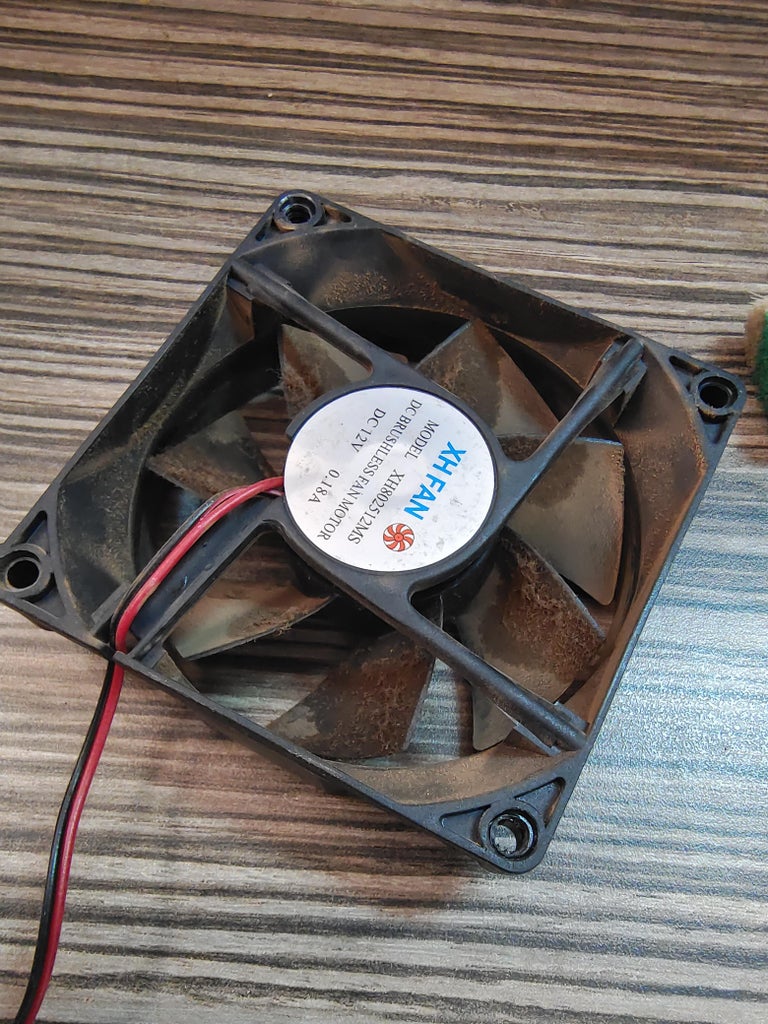

- Open the power supply with the help of screwdrivers.

- Clean the power supply from inside and outside.

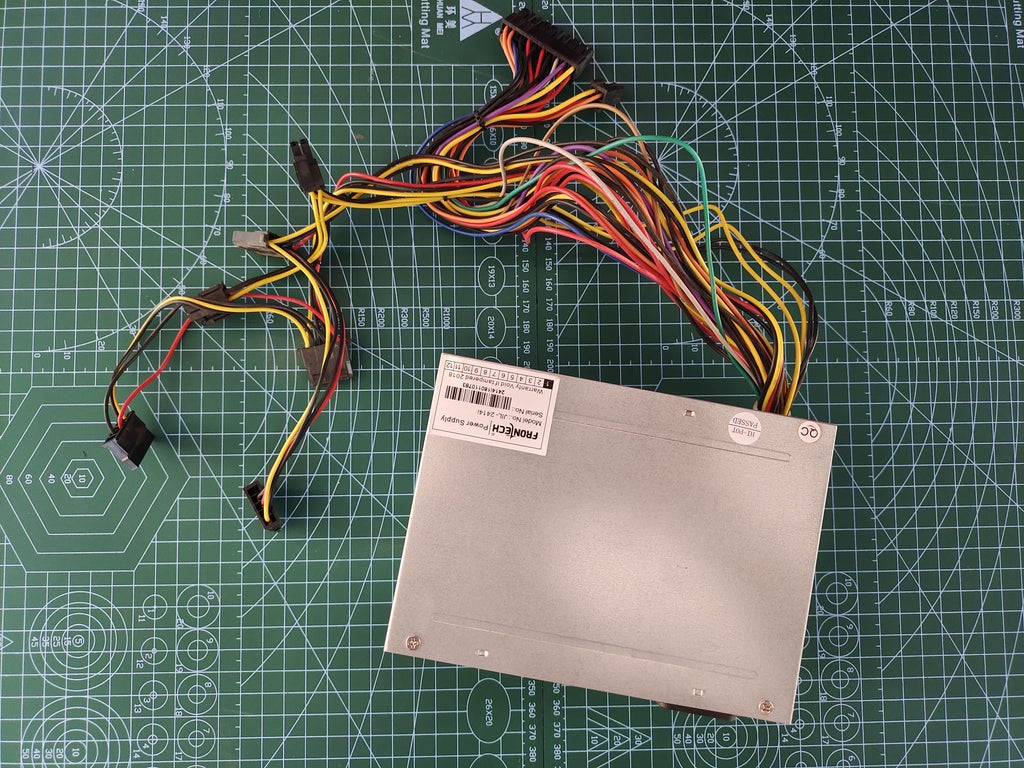

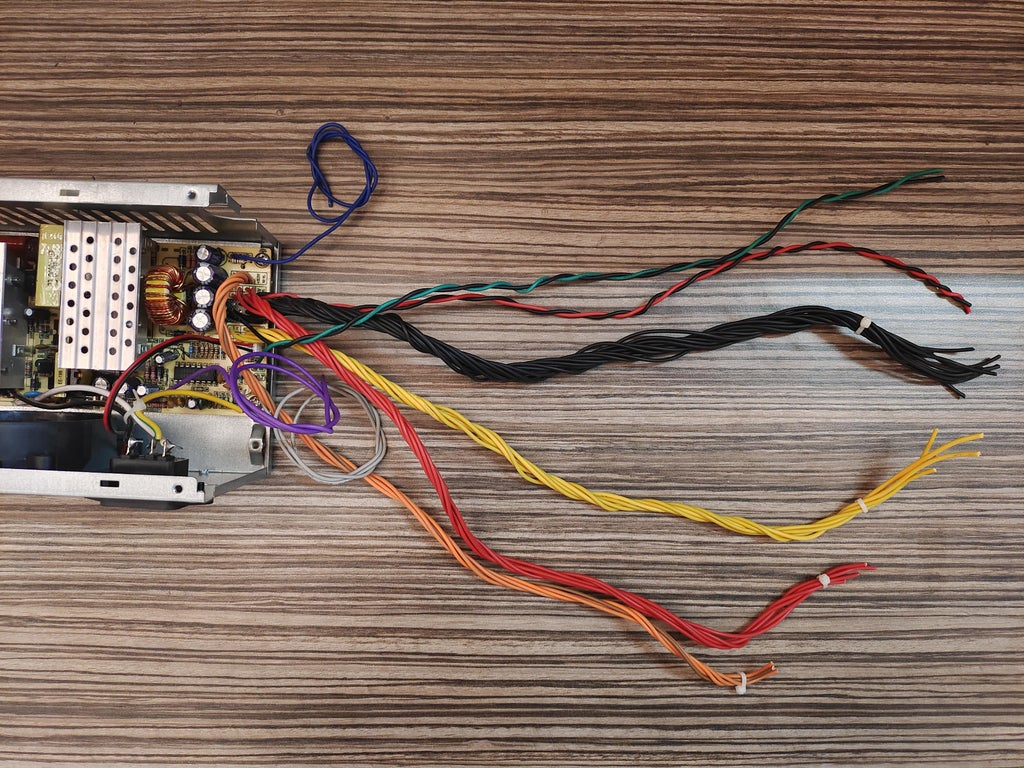

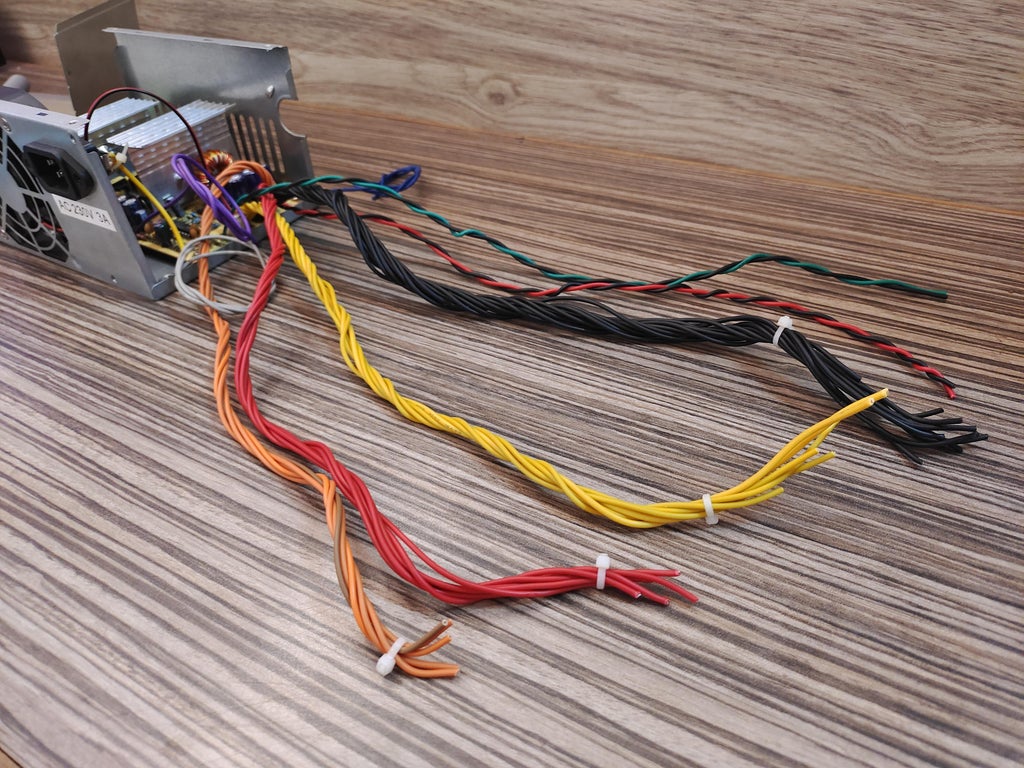

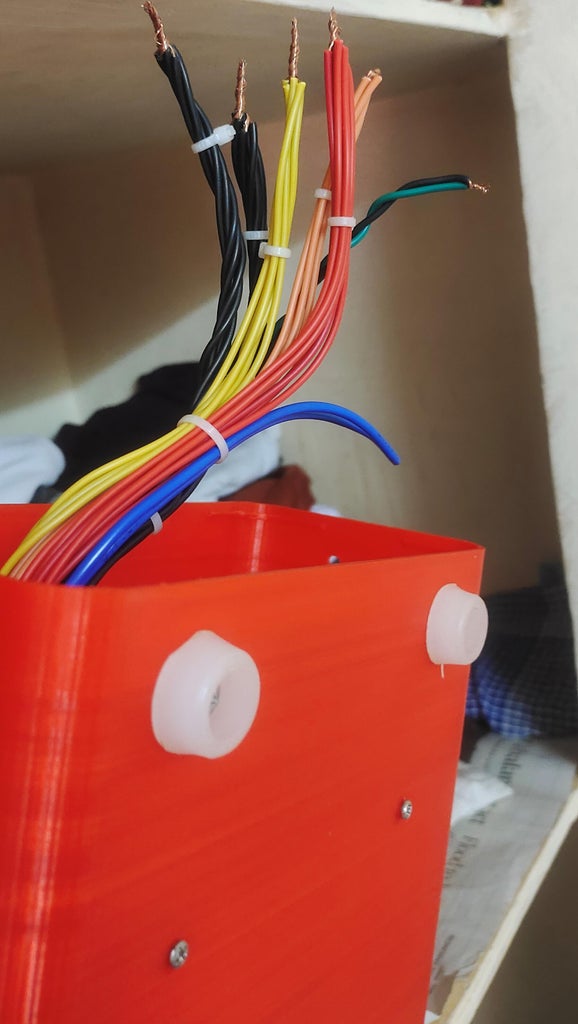

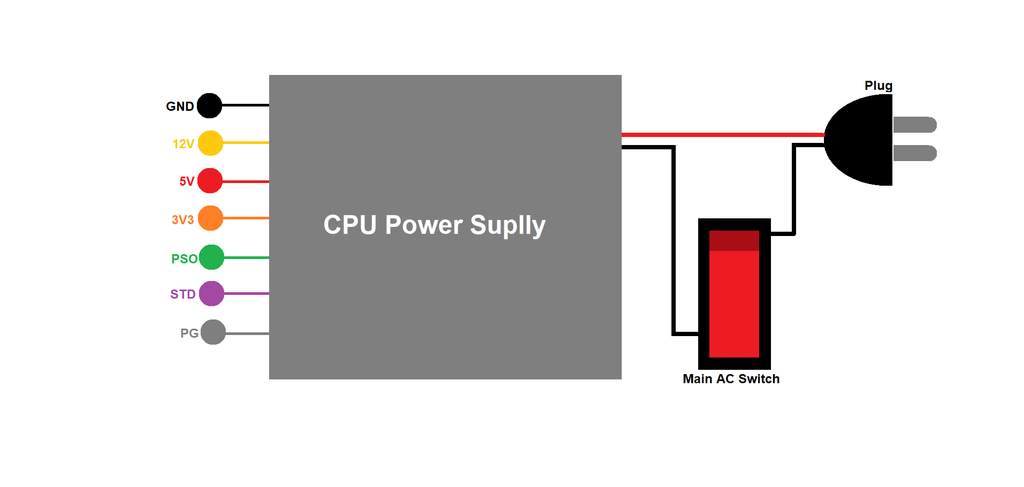

Step 2: Sorting the Power Supply Wires:

- Cut all the connectors.

- Separate the different colored wires and group the wires with same colors.

- Ground – (BLACK) – The Ground or reference.

- +5 V – (RED) – Positive 5 volts.

- +12 V – (YELLOW) – Positive 12 volts.

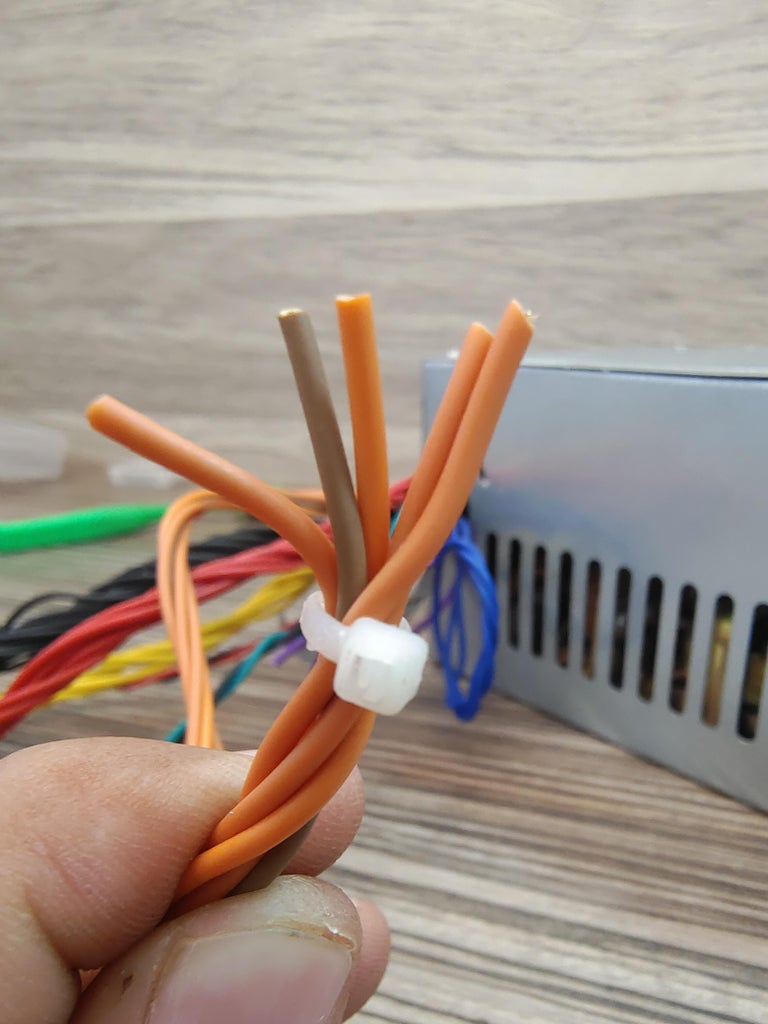

- +3.3 V – (ORANGE) – Positive 3.3 volts.

- -12 V – (BLUE) – Negative 12 volts.

- -5 V – (WHITE) – Negative 5 volts (not on later models).

- PS-ON – (GREEN) – Power Switch On. Connect to Ground to turn on the power supply.

- PG – (GREY) – Power Good. A status voltage that is 5 volts when power is good.

- 5V Standby – (PURPLE) – Standby voltage, 5-volts at up to 2 amps. On when supply is powered up.

- Group Green and one Black wires.

- Group one Red and one Black wires.

- Group the Brown wire with Orange Wires.

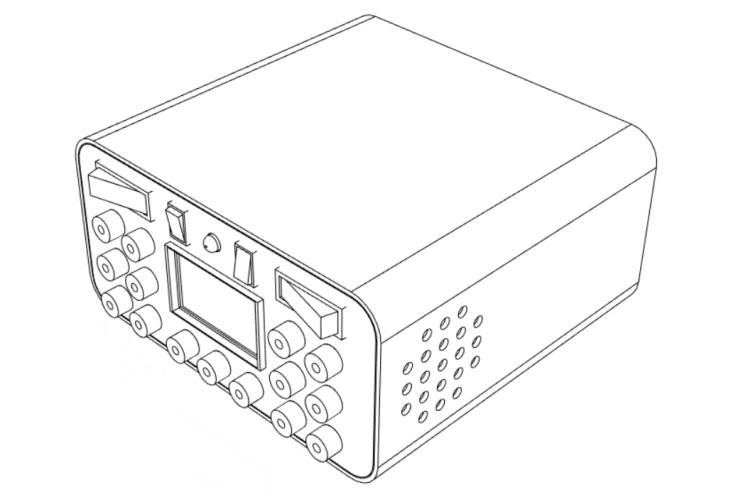

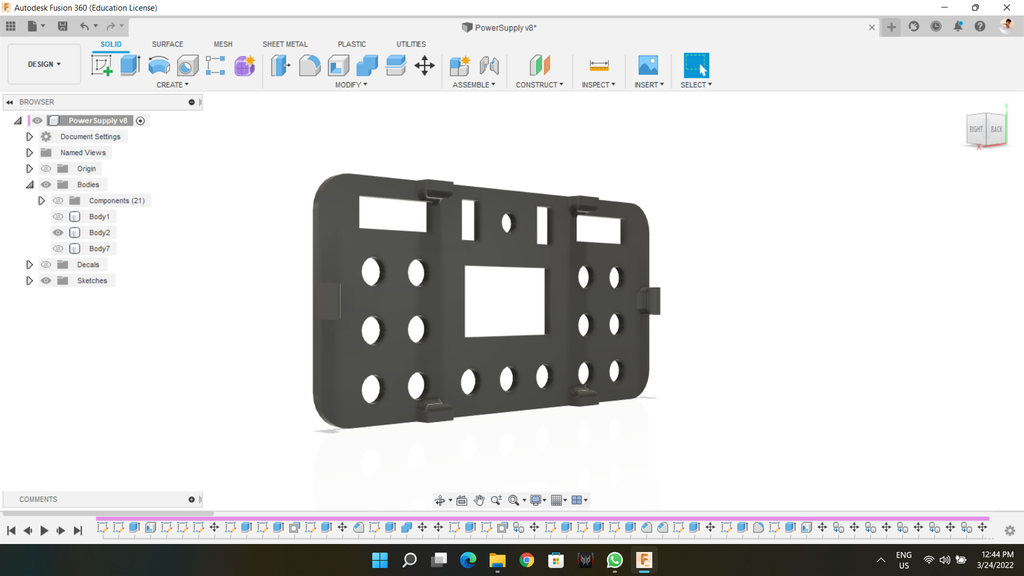

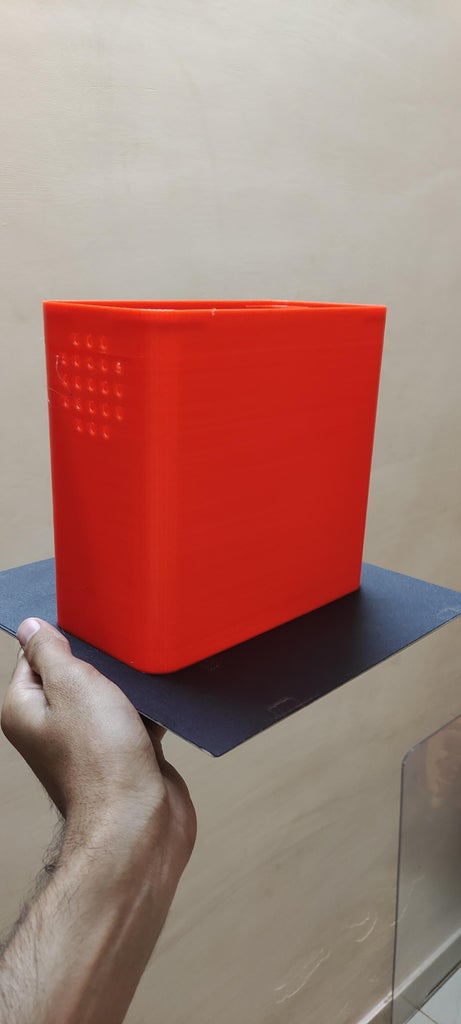

Step 3: 3D Printing:

- Download the stl files from below CAD section.

- and 3D Print them (There are two different types of main body and front panels print any one set).

- Fusion 360 File , You can make changes in the design using Fusion 360.

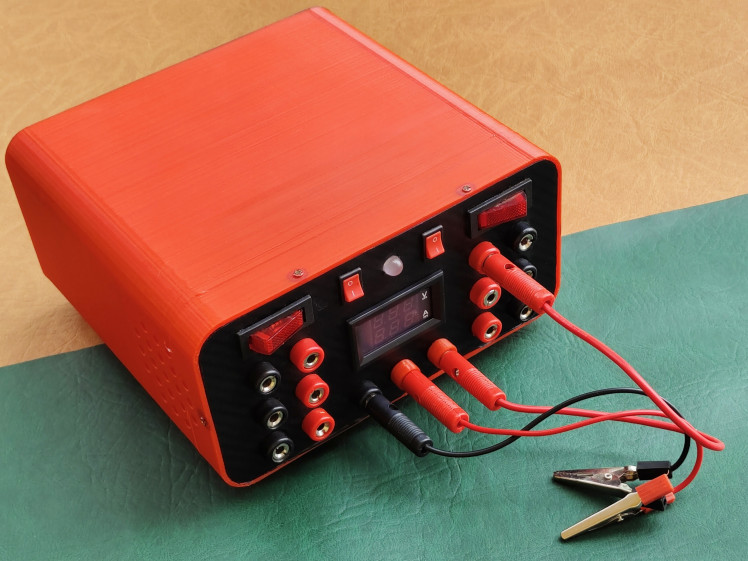

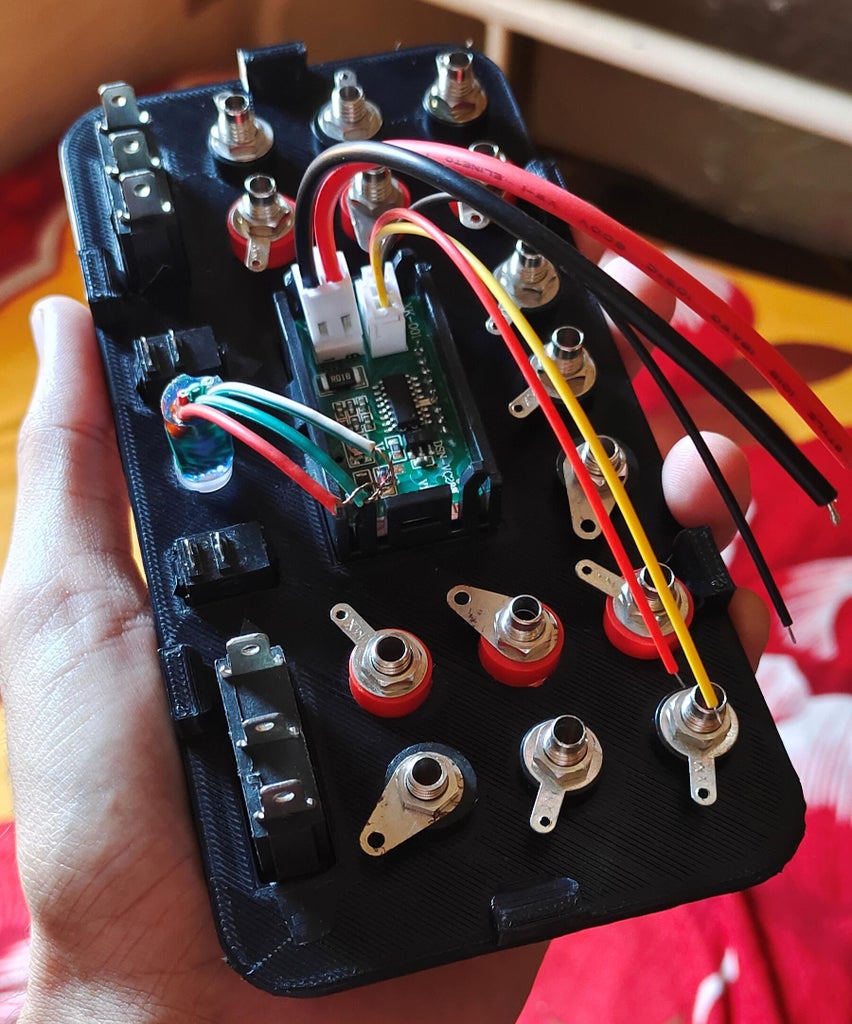

Step 4: Components Assembly:

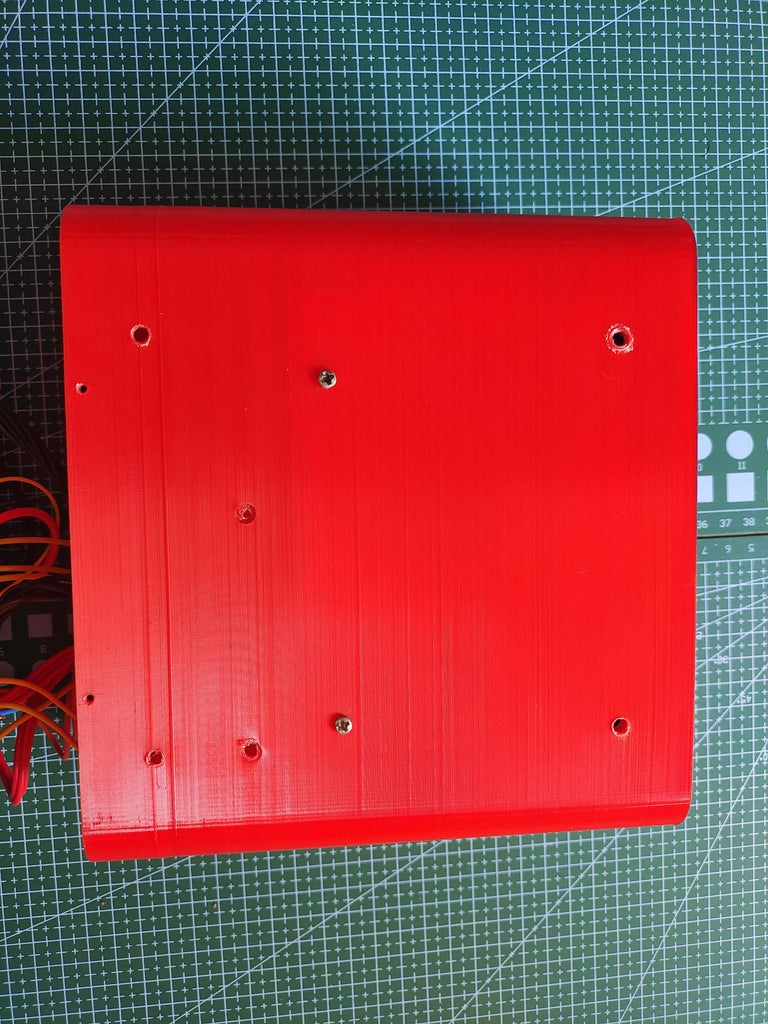

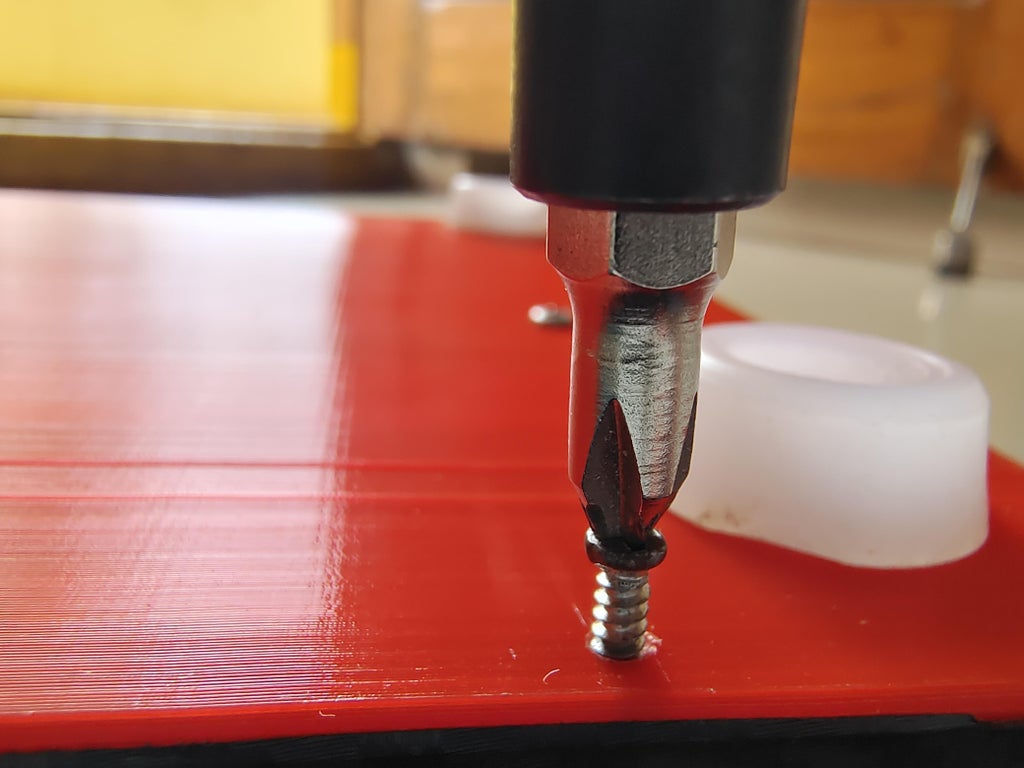

- Drill few holes using the drill machine wherever you thing is necessary .

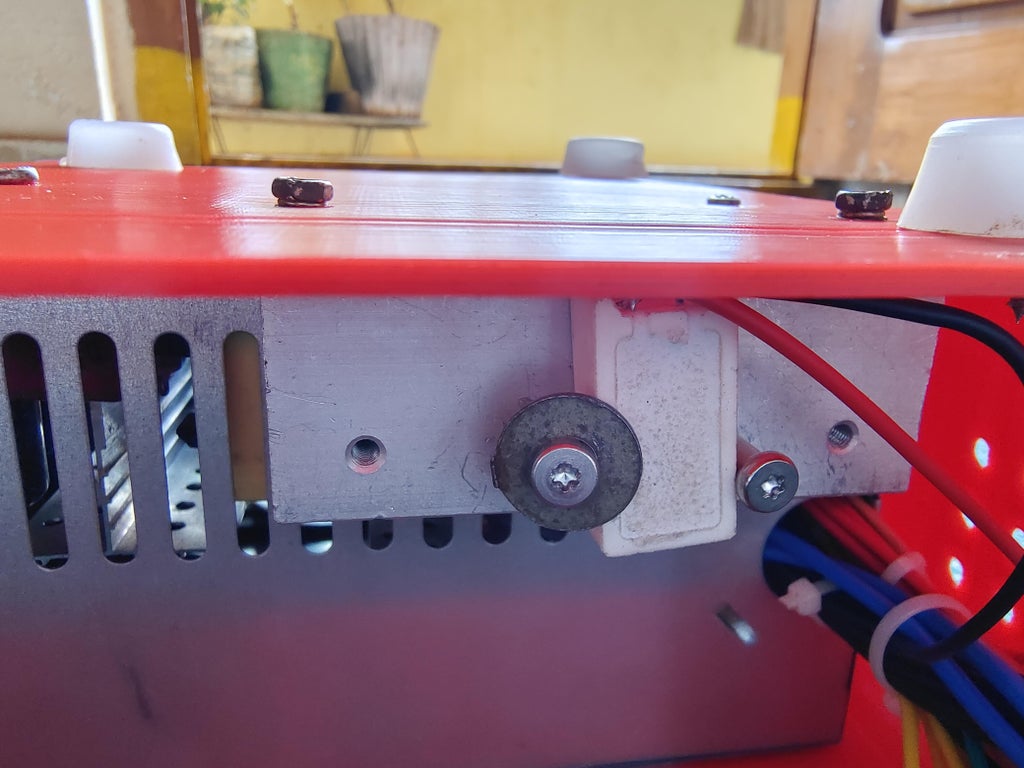

- I have drilled 4 holes through the body and power supply to screw the power supply to the body.

- Also put the rubber foots using the screw.

- Remove the insulations from the wires tie them with zip tries.

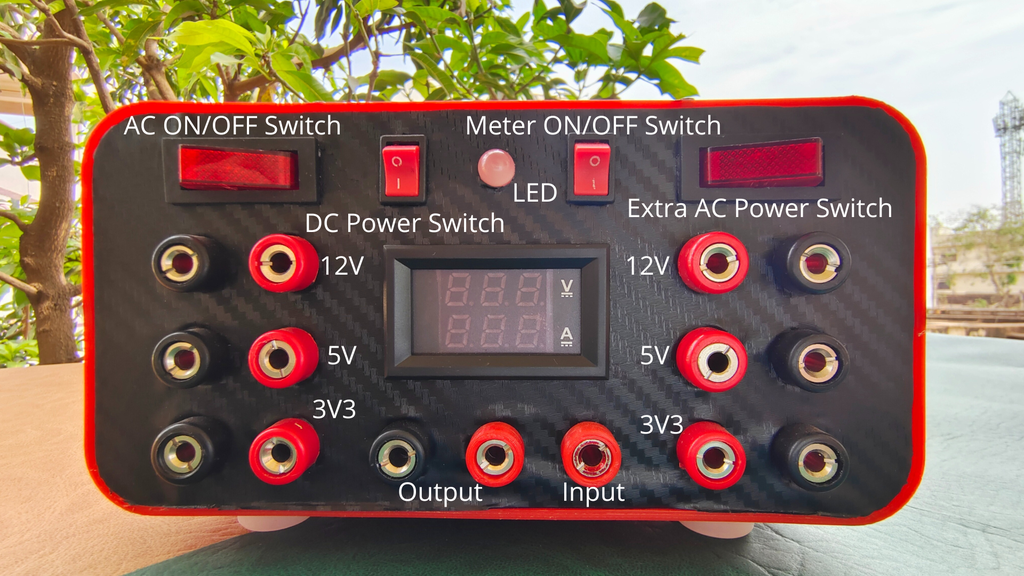

- I covered the front panel with black textured sticker because I was not satisfied with the quality of the print (optional).

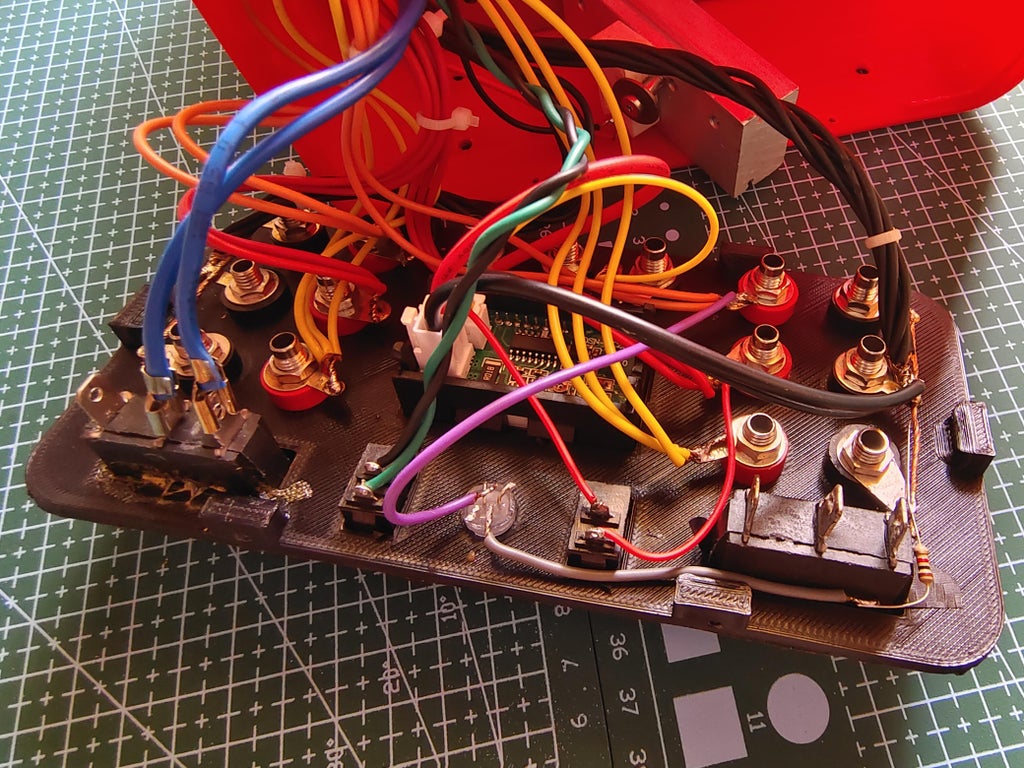

- Now add all the components(Banana Connectors, Switches and the Digital Meter) to the front panel.

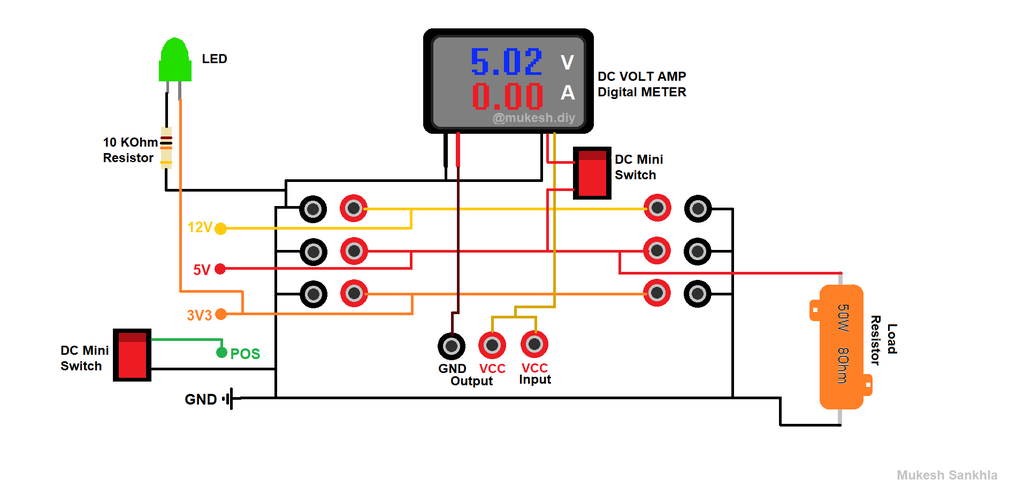

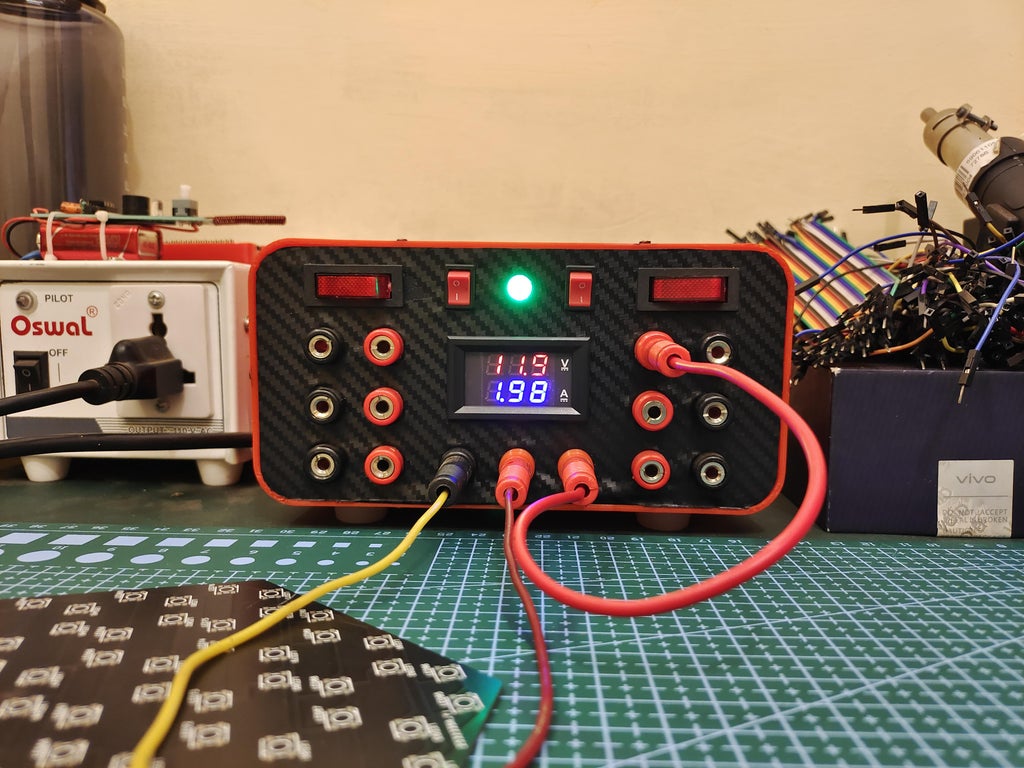

Step 5: Circuit Connections:

- Make all the connections as shown in the Circuit Diagrams

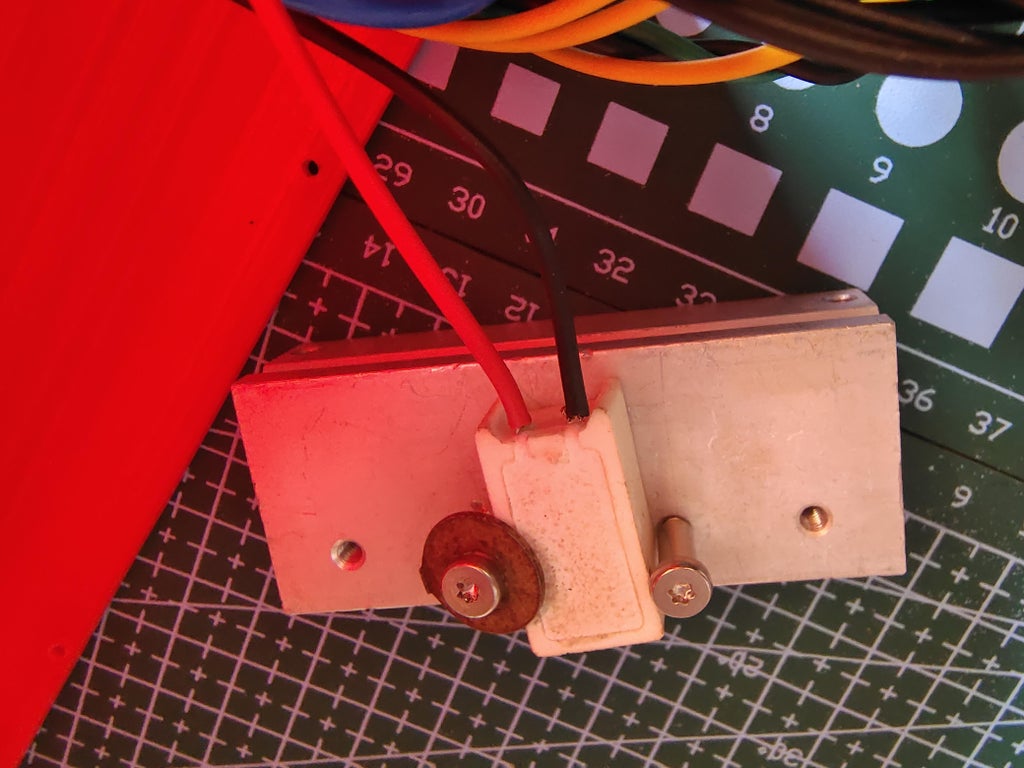

- I added a aluminum heatsink to the resistor since my resistor didn't come with aluminum body.

- I added one extra AC switch which has no connections, I used it for future use.

Step 6: Final Assembly:

- Fix the Resistor and Fix the front using some screws.

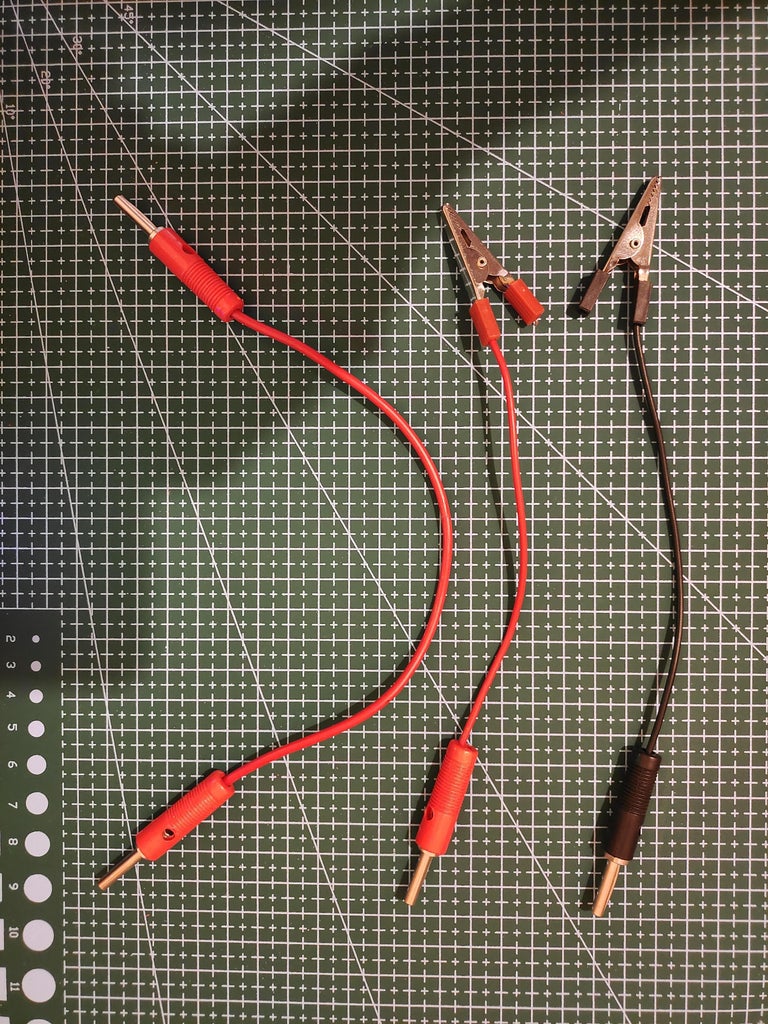

Step 7: Banana Connectors:

- I made few connecting wires using some banana and alligator pins.

Step 8: How to Use:

- All Black stands for GND / -Ve

- All Red stands for Vcc / +Ve

- At the input we have to connect one of the +Ve voltage( 3V3/5V/12V)

- At the output we can connect the DC Device.

- The voltage and ampere of the device can be monitored on the digital using Output connectors.

- And rest of the pins can be used directly.

Step 9: Problem With Initial Design:

- My design includes the computer power cable and connector, the problem with this back connector design is that the power supply does not goes flat with the wall occupying some space.

- My Solution is to print the MainBodyModified.stl and connect the cable directly by removing the connectors.

Schematics, diagrams and documents

CAD, enclosures and custom parts

Credits

mukesh-sankhla

🧑💻Passionate software engineer at Siemens, dedicated to driving digitalization by day. 🧑🏭By night, I'm a maker exploring IoT, product design, electronics, CAD, and 3D printing, sharing my projects with the world.

Leave your feedback...