Flex Pcb Based Actuator

About the project

A really useful thin actuator for your Projects

Project info

Difficulty: Moderate

Platforms: Texas Instruments, PCBWay

Estimated time: 1 hour

License: GNU General Public License, version 3 or later (GPL3+)

Items used in this project

Hardware components

Story

Flexible PCB actuators using neodymium magnets. These actuators leverage electromagnetic principles to perform various tasks, including actuation, vibration, sound production, and sensing. This project is inspired by Carl Bujega's FlexAR. This project showcases the broad potential of these actuators in various technological domains. A Huge Thanks to PCBWay for sponsoring this project.

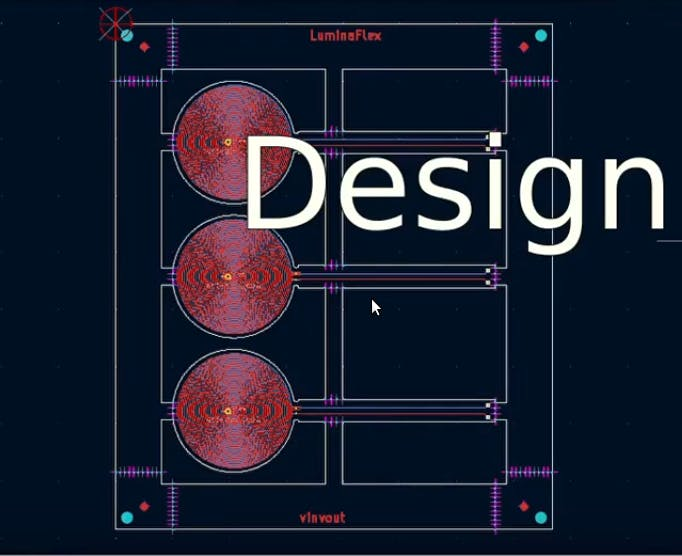

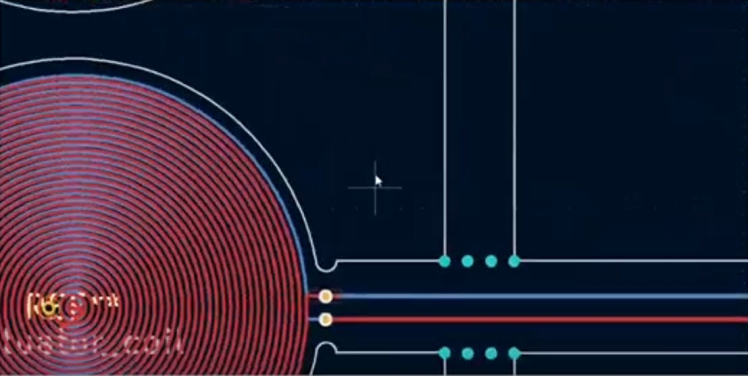

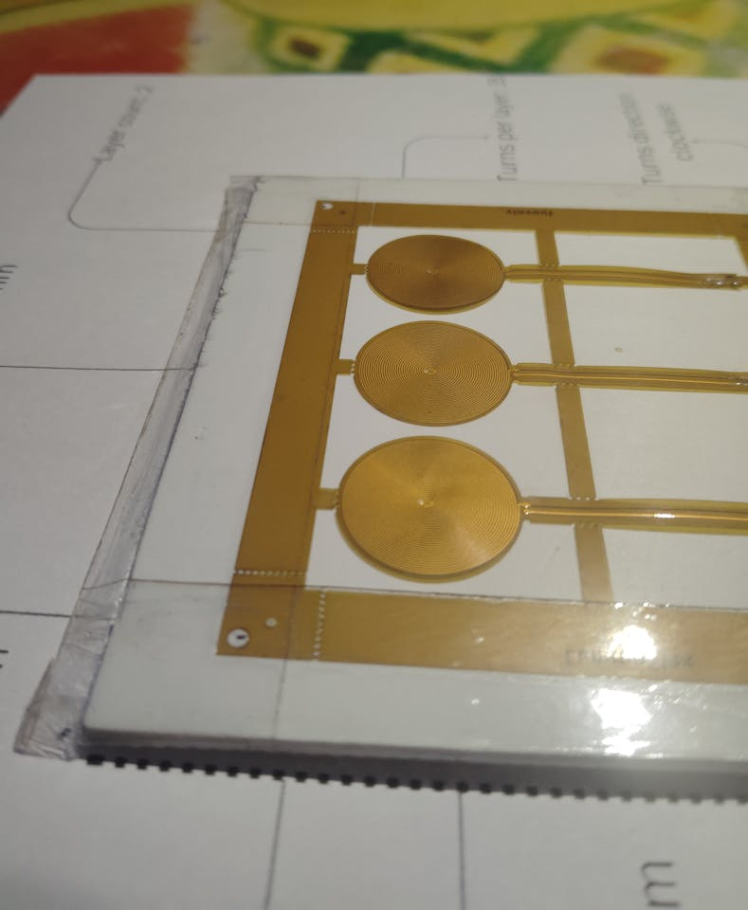

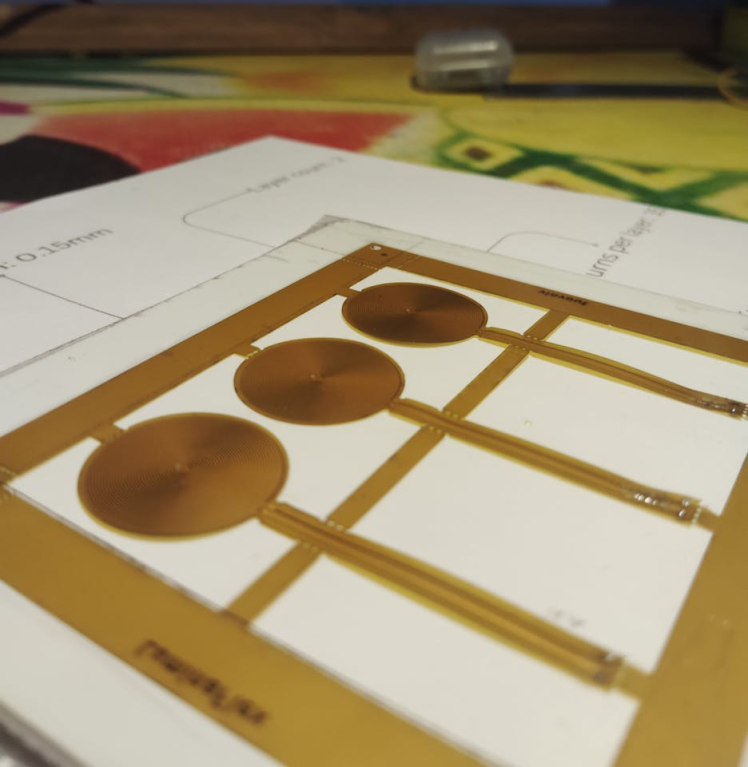

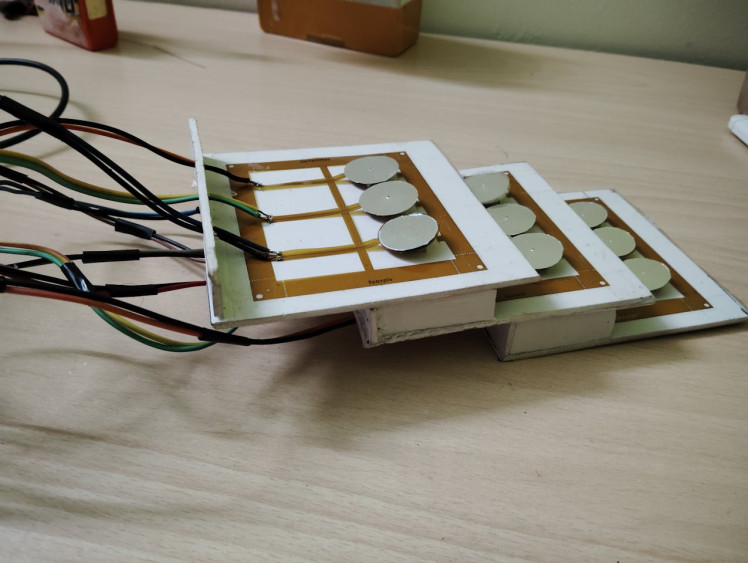

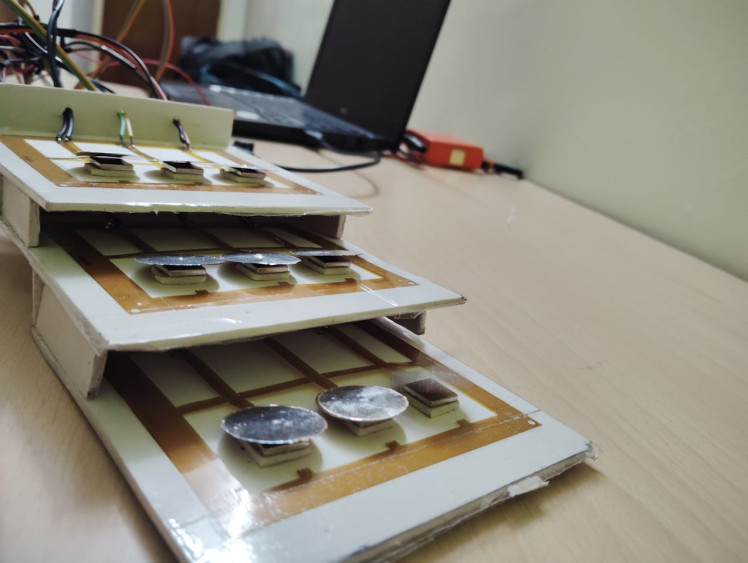

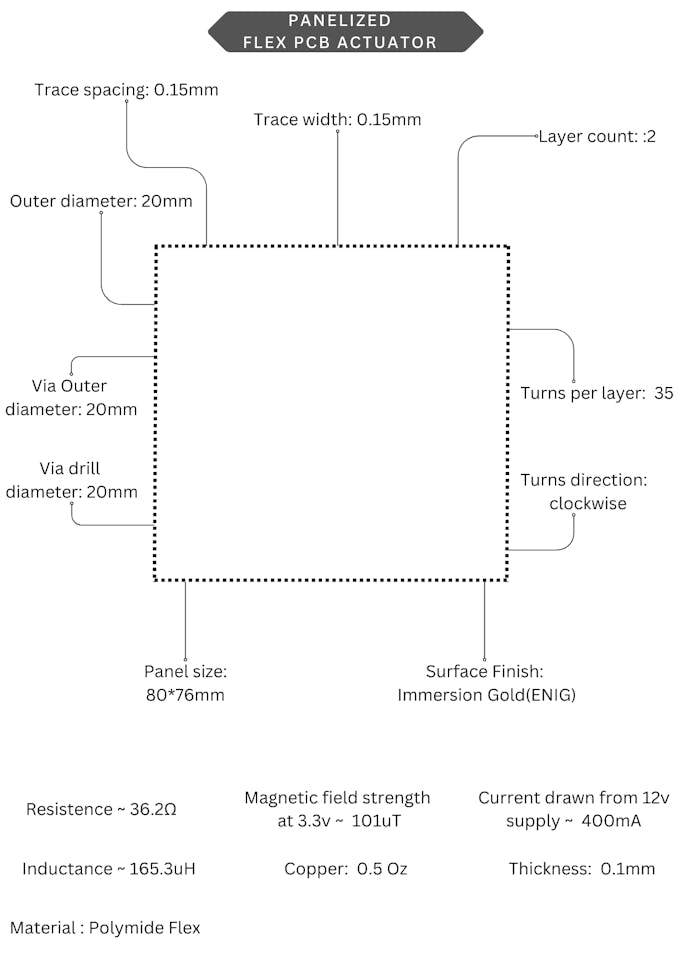

The flexible PCB actuators are designed with polyimide flex PCB material and copper traces. They actuate when subjected to an external magnetic field due to the Lorentz force generated by the current passing through the copper traces. The key components include a circular spiral inductor design with a straight arm for connectivity (The FlexPCB itself), and neodymium magnets for actuation. The neodymium magnets are placed directly under the Flex PCB Coils.

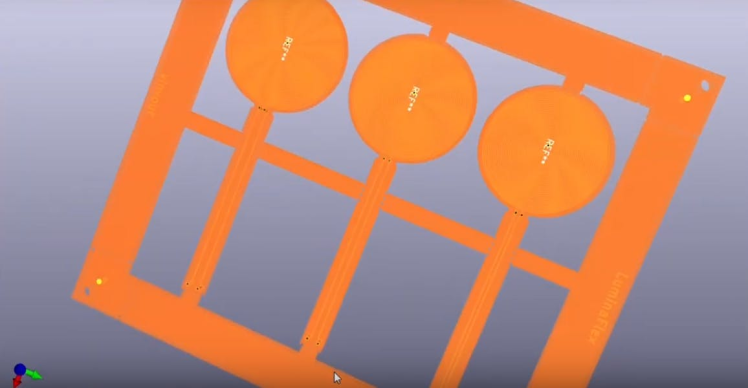

The design optimization involved implementing a curve shape at the junction between the coil and the arm to prevent tearing and setting the arm length to 5 mm to avoid excessive looseness. Panelization was adopted for cost efficiency, yielding 15 pieces in total compared to 5 pieces if not penalized.

1 / 2

The designs were sent to PCBWay for manufacturing, and engineering queries were resolved, ensuring our PCBs were fabricated flawlessly. A huge thanks to PCBWay for sponsoring these PCBs they provide high-quality PCB go check out PCBWay for your projects.

Why Choose PCBWay?

Quality: They take quality seriously. The PCBs I got are of excellent quality and they are of just 0.1mm thickness

1 / 2

Quick Turnaround: Time is of the essence in the tech world. PCBWay offers blazing-fast manufacturing and delivery times, so you can bring your ideas to fruition faster than ever before.

1 / 2

They also have really good customer service they asked me some engineer questions related to the designs, like the via I made for the coil wasn't actually at the center and they made sure that it wasn't a mistake

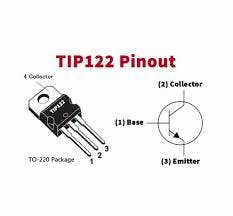

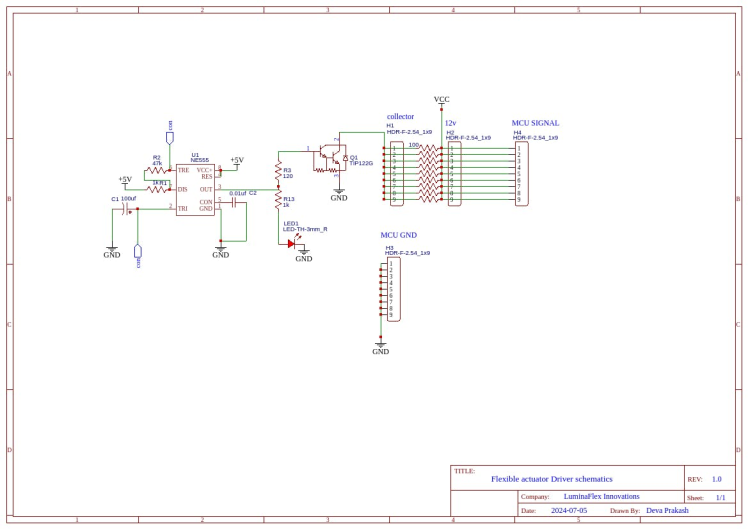

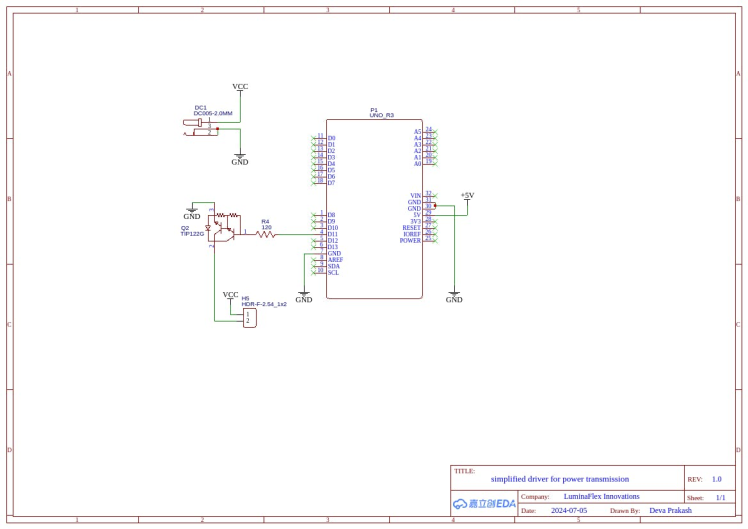

3.3TestingDuring testing, it was found that the initial current draw of 400 mA per coil was too high. To address this, a 100-ohm resistor was used to limit the current to 80 mA per coil. Additionally, the S9013 transistor could not handle more than 2 coils and would blow off when driving 3 coils, so it was replaced with a TIP122 for its higher current handling capacity (rated for up to 5A collector current).

The driver board design included a 555 timer for signal delivery at timed intervals, a 12V power supply, and TIP122 Darlington transistors for their higher current capacity.

The actuators can be used for precision control systems, soft robotic actuation, and vibrating devices by attracting or repelling due to magnetic fields. Additionally, they can provide haptic feedback through controlled vibrations, enhancing user interaction and tactile response in various applications.

4.2 Mirror Array SystemThe actuators can be used in mirror array systems for applications such as adaptive optics, laser beam steering, and other precision optical systems.

1 / 2

The actuators can produce sound when subjected to varying frequencies, making them suitable for miniaturized speakers or buzzers.

4.4 Wireless Conduction

The FlexPCB coil can induce a current in nearby coils through electromagnetic fields, enabling wireless power transmission.

4.5 Magnetic Field SensingThe actuators can also detect nearby metals by influencing the inductance of the coil in an LC oscillator circuit, making them useful for metal detectors and magnetic field sensors.

4.6 Artistic Installations (Origami)The actuators can be used to mimic movements such as butterfly flaps, making them ideal for interactive art installations and educational models.

4.7 Sliding Magnet MechanismThe actuators can slide a magnet across multiple coils through sequential actuation, useful for linear actuation systems and conveyor mechanisms.

4.8 Individual Panel Control with Microcontroller IntegrationThe flexible PCB actuators can be integrated with a microcontroller to enable individual control of each coil. This capability allows for precise and customized activation of specific actuators based on programmed instructions, enhancing versatility in applications such as adaptive structures.

4.9 Precision Positioning SystemsThe actuators could be adapted for use in precision positioning systems where the mirror's position needs to be adjusted with high accuracy, such as in laser alignment systems or in experimental setups requiring controlled optical paths.

4.10 Scientific Studies and ResearchThe actuators have potential applications in scientific studies and research contexts, where precise control of optical elements is essential for achieving high-quality measurements and imaging.

5. Parameters

6.Future Considerations

Future improvements include increasing coil layers for enhanced strength, adding arm stiffeners for durability, increasing turn numbers for stronger magnetic fields, exploring the impact of different frequencies on actuation, and increasing the pad size of the coil for improved soldering and mechanical stability.

7. ReferenceResearch by Carl Bujega provided foundational insights into the design and application of flexible PCB-based actuators, serving as an inspiration for this project. Thank you.

Watch this video for more information

Leave your feedback...