Texas Instruments C2000 Series: Integrating Edge AI for Smarter, Safer Motor Control

Texas Instruments has introduced an edge AI-based motor fault detection solution within its C2000 series microcontrollers (MCUs), a trusted technology in real time motor control. By leveraging machine learning to detect and prevent potential motor faults in real-time, this update represents a significant advancement for industrial automation. The integration of Edge AI into these MCUs allows for smarter, safer, and more efficient operations, supporting factories in predictive maintenance without relying on cloud connectivity.

Overview of TI’s Edge AI Technology in the C2000 Series

Texas Instruments’ C2000 series microcontrollers, known for precise motor control, now feature integrated Edge AI capabilities. This new technology leverages machine learning algorithms and advanced signal processing to analyze motor health directly on the device, enabling real-time fault detection. By offloading AI computations to a dedicated neural processing unit (NPU), the C2000 performs both motor control and predictive maintenance simultaneously.

Key Features of TI’s Edge AI Motor Fault Detection

Texas Instruments’ edge AI motor fault detection solution is built around several advanced features that enhance its real-time performance and efficiency:

- Edge AI Processing: The Edge AI model processes data locally on the MCU, reducing latency and bandwidth needs. This on-device computation allows for real-time anomaly detection and quick responses to potential issues.

- Signal Processing Techniques: TI’s solution employs sophisticated methods, including:

- Vibration Analysis: Detects imbalances, misalignments, or mechanical wear in motor systems.

- Current Signature Analysis: Monitors electrical patterns to identify changes indicative of faults.

- Temperature Monitoring: Tracks thermal performance to prevent overheating and related failures.

- Integrated Neural Processing Unit (NPU): The NPU on the TMS320F28P550SJ MCU provides power efficiency and low latency, enabling real-time fault detection without affecting motor control performance.

Benefits of Edge AI in Industrial Applications

Integrating Texas Instruments’ Edge AI technology into motor control applications brings several key advantages to industrial environments:

- Proactive Maintenance: Real-time monitoring allows facilities to detect and address motor issues before they escalate, reducing unplanned downtime and maintenance costs.

- Increased Reliability: Continuous analysis of motor health minimizes unexpected failures, enhancing operational reliability.

- Enhanced Safety: Early fault detection reduces the risk of catastrophic failures, creating a safer work environment.

- Data-Driven Insights: Real-time analytics empower maintenance teams with actionable data, optimizing both maintenance and operational strategies.

Practical Application and Demo Insights

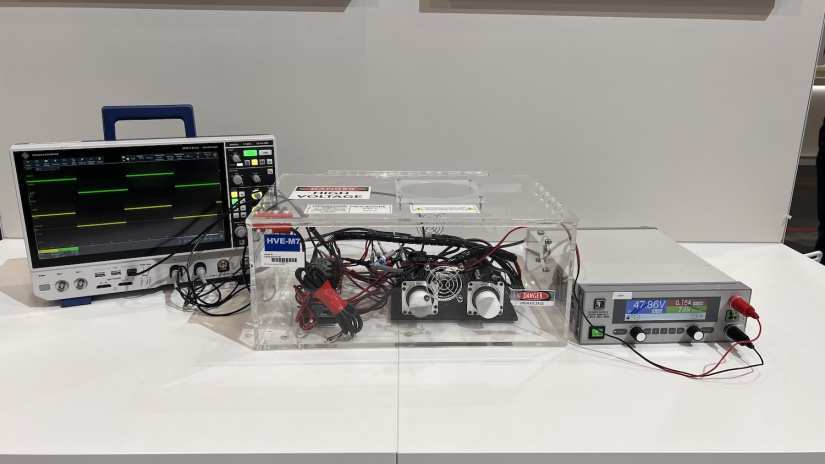

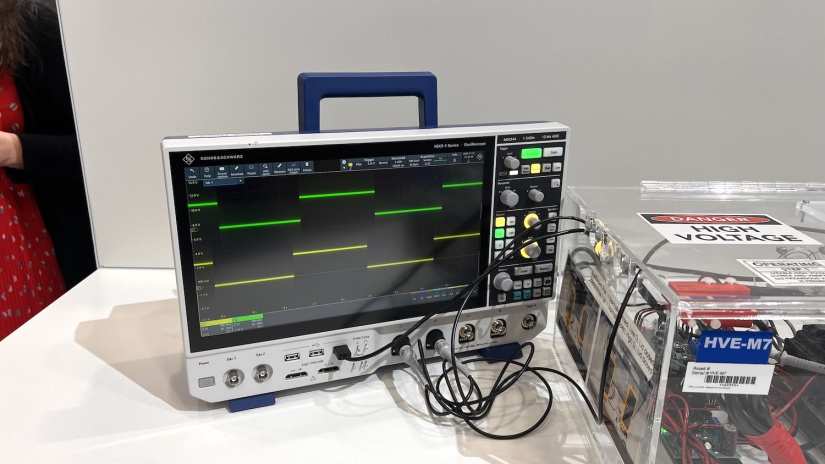

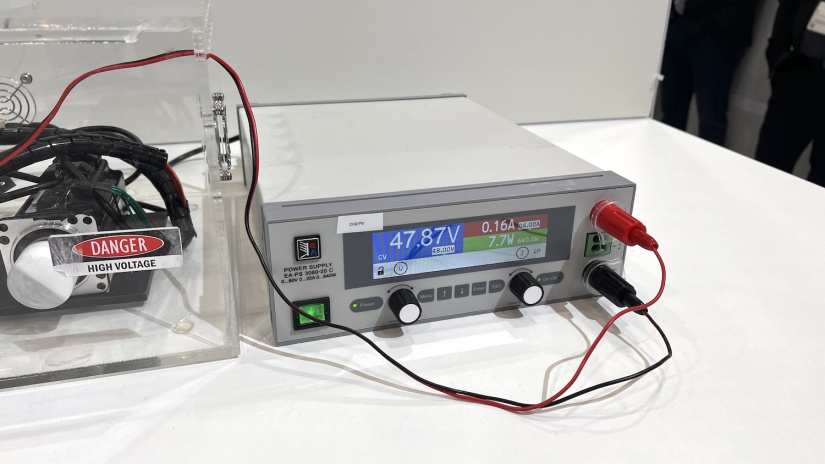

At Electronica 2024, Texas Instruments showcased a demo featuring their TMS320F28P550SJ MCU running an edge AI-based motor fault detection model. The demo highlighted how the MCU could control two motors while simultaneously performing fault detection using a neural network model. This setup also demonstrated TI’s embedded AI toolchain, illustrating the ease of integration and real-time capabilities of the C2000 series for industrial use.

The demo’s focus was on how the dedicated Neural Processing Unit (NPU) within the TMS320F28P550SJ offloads model execution from the main CPU, preserving computational bandwidth for motor control and other critical tasks. This configuration offers a tangible look at how TI’s C2000 MCUs can enhance factory operations through on-device predictive maintenance, paving the way for more efficient and safer industrial environments.

Final thoughts

Texas Instruments’ Edge AI-enabled C2000 series MCUs present a robust solution for real-time motor fault detection, contributing to safer and more efficient industrial operations. With an integrated toolchain, advanced processing capabilities, and practical applications in predictive maintenance, the C2000 series empowers engineers to transform motor control and reliability. By detecting faults in real time, TI’s solution helps industries prevent costly downtime and optimize maintenance practices.

To learn more about Texas Instruments’ Edge AI technology and the C2000 series MCUs, explore TI’s Edge AI technology page and find out how to start implementing smarter motor control in your systems.

Leave your feedback...