Project Binky’s Ingenious 3D Printed Circuit Board Solution

Project Binky by Bad Obsession Motorsport has become an iconic YouTube series for car enthusiasts and engineering fans. In this series, the team tackles the ambitious restoration and customization of an Austin Mini GT4, blending classic car preservation with inventive, modern engineering solutions. Known for its meticulous attention to detail, Project Binky captures the balance of vintage aesthetics with advanced DIY techniques, making it a must-watch for anyone intrigued by creative problem-solving and the art of automotive restoration.

Watch Ian talk about the Project Binky's restoration of an Austin Mini in this episode of The Electromaker Show

The Challenge of Upgrading Vintage Gauges with Modern Circuitry

Retrofitting Classic Gauges with Modern Electronics

The team at Bad Obsession Motorsport faced a unique challenge with the Austin Mini GT4’s original dashboard. Their goal was to maintain the classic appearance of the vintage gauges while upgrading the electronics to ensure reliable, modern functionality. This required careful planning to blend old components with new circuit elements in a way that retained the car’s vintage charm without compromising on performance.

Creative PCB Design

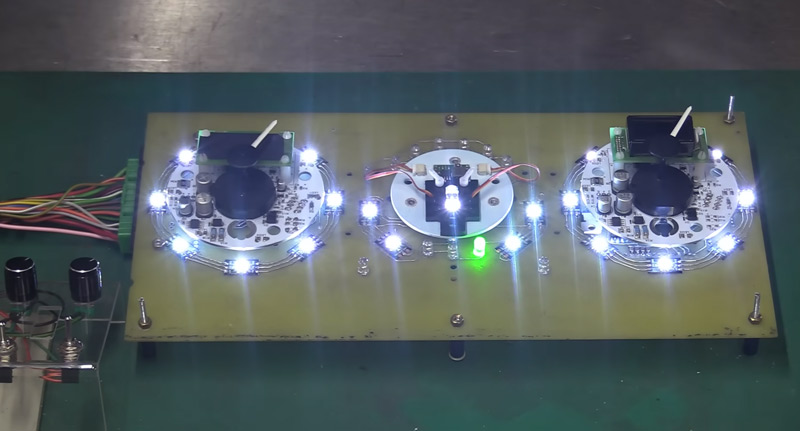

To overcome the limitations of outdated wiring, the team designed a custom circuit board tailored to fit behind the existing gauge setup. This DIY PCB not only replaced the old wiring but also ensured compatibility with the car’s vintage layout. The intricate work allowed the team to modernize the dashboard’s function, paving the way for improved reliability and functionality while keeping the original design intact.

The Ingenious 3D Printer Soldering Solution

Finding a DIY Solution for Circuit Tracing

When it came to creating traces for their custom PCB, the team encountered a roadblock. Instead of outsourcing the task to a fabrication service, they devised an in-house solution by repurposing a 3D printer to lay down solder traces. Noting the similar melting points of 3D printer filament and solder, they experimented with using the printer to place the solder directly, allowing them to complete the circuit board in a creative, cost-effective manner.

Benefits of the 3D Printing Approach

This innovative use of a 3D printer provided several advantages, from saving costs to enabling greater control over the project. The approach allowed the team to make on-the-fly adjustments, resulting in a clean and functional PCB with well-adhered solder traces. This method highlights the team’s resourcefulness and ability to find practical solutions, showcasing an inventive approach to DIY electronics.

Project Binky’s Cult Following and Engineering Dedication

A Series with Staying Power

Project Binky has built a dedicated following over its 11-year journey, capturing audiences with its detailed focus on restoration and engineering. This longstanding series has earned a loyal fan base not just among car enthusiasts but also among those who appreciate the ingenuity and dedication required in complex DIY projects.

The Enthusiasm and Precision Driving Project Binky

With a blend of humour, authenticity, and meticulous attention to detail, the team at Bad Obsession Motorsport shares their passion for overcoming engineering challenges. Their commitment to pushing the boundaries of automotive and tech DIY has made Project Binky a landmark series, inspiring a wide audience with their innovative approach to classic car restoration.

Did you enjoy this article?

Make sure you subscribe to The Electromaker Show for similar content and subscribe to our monthly newsletter!

Leave your feedback...