No-Code Automation: Tactun Shines at Embedded World 2024

Among the plethora of innovations at Embedded World 2024, a standout demonstration by Tactun captivated attendees, offering a glimpse into the future of no-code automation in manufacturing processes.

The Innovation at Embedded World 2024: Tactun's No-Code Platform

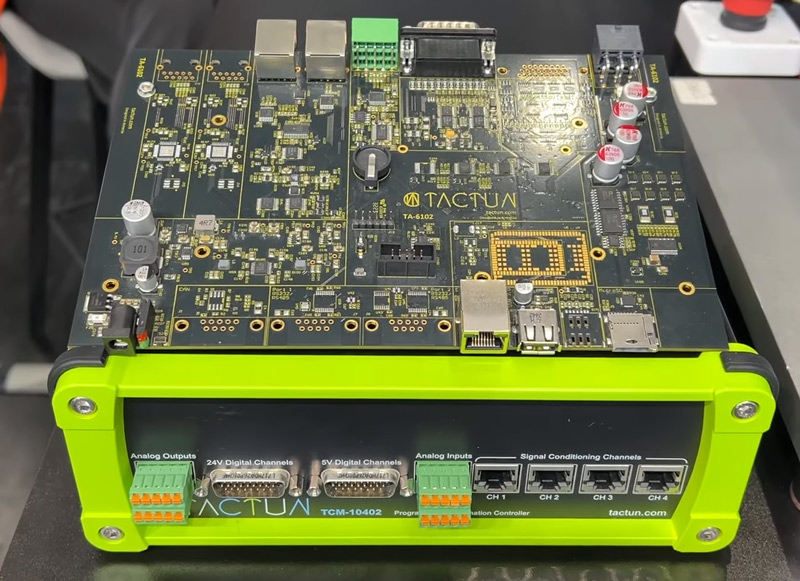

Amidst the bustling halls of Embedded World 2024, Tactun demonstrated a unique technology set to revolutionize the way manufacturers interact with automation. Vah from Tactun introduced us to a groundbreaking controller that is not only adept at reading data from sensors and controlling motors with unparalleled precision but does so through a no-code platform. This paradigm shift allows manufacturers to easily configure and control their equipment, ushering in a new era of accessibility and efficiency in manufacturing automation.

The No-Code Platform: A Closer Look

Drawing parallels to the intuitive interfaces of digital audio workstations and video editing software, Tactun's no-code platform redefines the approach to programming automation systems. With its intuitive block-based configuration, users can specify motor actions, set transitions, and establish operational rules without writing a single line of code. This platform incorporates essential safety measures to prevent equipment damage, ensuring a seamless and secure operational flow. Furthermore, the platform's versatility extends to the creation of customized dashboards and the integration of both physical and software buttons, offering an unparalleled level of control and personalization.

Real-World Applications and Benefits

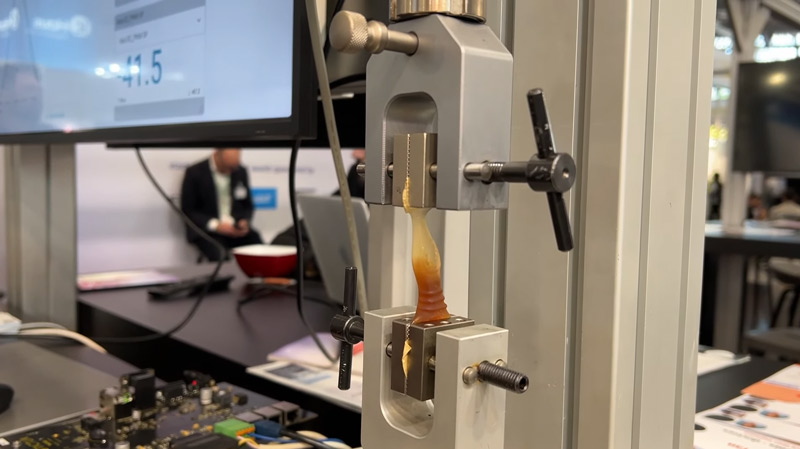

In a compelling demonstration, Tactun showcased the platform's capabilities through a real-world application: testing the material properties of a Cola sweet. This example highlighted not just the platform's precision in measuring stress and deformation but also its ability to record comprehensive data over time, paving the way for the development of more resilient materials. The incorporation of a Newton meter to accurately measure force exerted, coupled with precise movement tracking, showcases the platform's advanced technical precision and its potential to drive significant advancements in material science and manufacturing processes.

Leave your feedback...