How to maximize PCB Design Efficiency with free online tools

The PCB manufacturing sector continues to depend on the Ucamco Gerber standard for conveying PCB production information to manufacturers, frequently situated abroad. Although the 2D image format helps bridge language gaps, the terminology of PCB Design for Manufacture often confuses novice designers. Moreover, the separation between PCB design and manufacturing persists as a costly barrier, resulting in missed deadlines, inconsistent production runs, and products that fail prematurely.

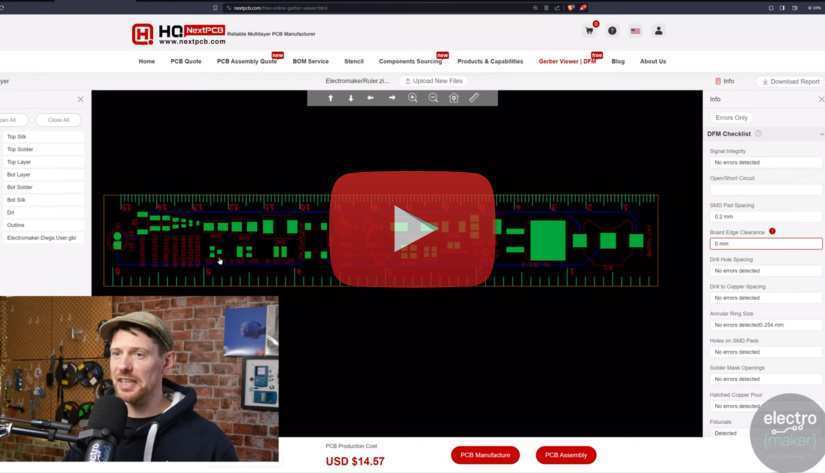

Watch Ian discuss NextPCB's Online Gerber Viewer in this episode of The Electromaker Show

HQ NextPCB, a leading provider in the electronics manufacturing service (EMS) industry, offers a suite of online tools that cater to the needs of both novice and experienced PCB designers. We explore the functionalities and benefits of NextPCB's offerings, with a particular focus on their Online Gerber Viewer and Design for Assembly (DFA) analysis tool.

Exploring NextPCB's Online Gerber Viewer

NextPCB's Online Gerber Viewer is a vital tool for PCB designers, offering a comprehensive solution to visualize and inspect Gerber files directly in your web browser. This advanced viewer is designed to accommodate users at all levels, from hobbyists to professional engineers, providing a clear, detailed view of PCB designs without the need for specialized software installations.

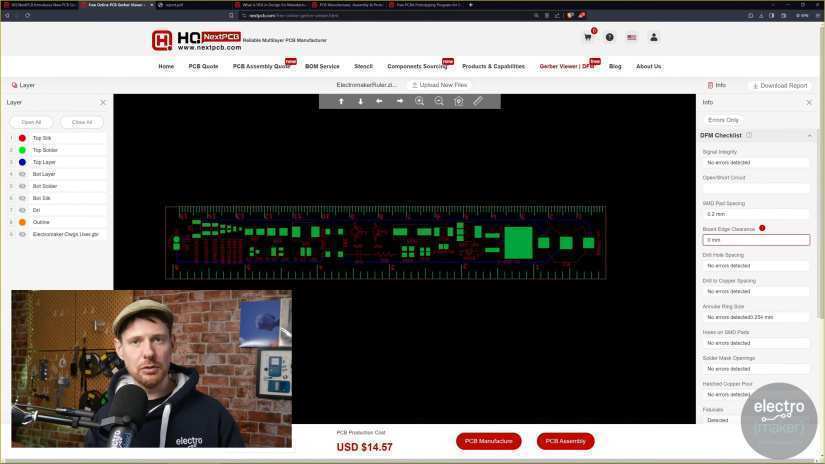

One of the key features of the Gerber Viewer is its error-checking capability. It goes beyond mere visualization; the tool automatically analyzes uploaded Gerber files for common and complex errors that could affect the manufacturability of the PCB. Issues such as insufficient board edge clearance, inadequate pad spacing, or incorrect pad sizes are flagged, allowing designers to address potential problems before proceeding to the manufacturing stage. This proactive approach to error detection is invaluable, ensuring that PCB designs are optimized for success from the outset.

Understanding Design for Assembly (DFA) with NextPCB

Design for Assembly (DFA) is a crucial concept in PCB design, emphasizing the importance of creating designs that are not only functional but also manufacturable. This tool assesses PCB designs for potential assembly issues, ensuring that components fit correctly and are appropriately spaced for automated assembly processes. By prioritizing DFA, designers can significantly reduce the risk of costly reworks and delays, streamlining the path from design to production.

A compelling case study that illustrates the practical benefits of DFA analysis involves the adaptation of the Electromaker PCB ruler into a functional circuit. The original design, while innovative, encountered several manufacturability issues, such as inappropriate pad sizes and insufficient board edge clearance. NextPCB's DFA tool was able to identify these issues which means the next iteration can be manufactured without issues. This example underscores the value of DFA in identifying and rectifying design oversights, ensuring a smoother transition to the assembly stage.

NextPCB's Commitment to Streamlining PCB Manufacturing

NextPCB has taken significant strides in revolutionizing the PCB manufacturing process, particularly with their offer of free PCBA (Printed Circuit Board Assembly) manufacture for businesses. This initiative is designed to lower the barriers for businesses looking to prototype or produce their PCB designs, providing a cost-effective solution without compromising on quality or efficiency.

The benefits of utilizing NextPCB's services extend far beyond cost savings. Their comprehensive approach to PCB manufacturing includes advanced online tools like the Gerber Viewer and DFA analysis, which work in tandem to ensure designs are optimized for manufacturing. This not only speeds up the production process but also minimizes the risk of errors and reworks, leading to a more efficient production timeline. Furthermore, NextPCB's commitment to customer support and its extensive experience in the industry make it a reliable partner for businesses of all sizes, ensuring that every project is met with precision and expertise.

Wrapping Up

NextPCB's suite of online tools, including the innovative Online Gerber Viewer and the comprehensive Design for Assembly (DFA) analysis, represents a significant leap forward in PCB design and manufacturing. These tools not only simplify the design process but also ensure that designs are optimized for manufacturing, reducing the likelihood of costly errors and reworks. With the addition of free PCBA manufacture for businesses, NextPCB is setting a new standard for accessibility and efficiency in the PCB manufacturing industry.

Did you enjoy this article?

Make sure you subscribe to The Electromaker Show for similar content and subscribe to our monthly newsletter!

Leave your feedback...