Maker Board Spotlight: Arduino Portenta Machine Control

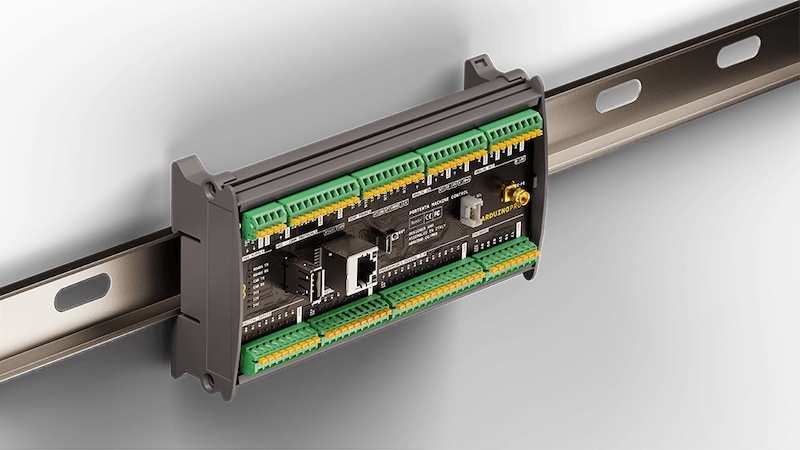

Arduino Pro added a new product for edge AI and industrial automation for the evolving Industrial Internet of Things (IIoT) with expanded capabilities - Arduino Portenta Machine Control. This industrial-grade hardware comes to fulfil the requirements of Industry 4.0 and the massive demand for edge AI and industrial automation. The product comes to market with the addition of Industrial IoT capabilities to standalone industrial machinery for smart manufacturing.

The ability to process real-time data from the factory machines, taking advantage of improved sensor technology, has benefited the growth of industrial automation. The support to control equipment remotely brings in the added functionality to the powerful industrial Arduino board that can be managed through the Cloud. Moreover, the hardware can be programmed using the famous and easy-to-use Arduino framework and other embedded development platforms.

One of the reasons it is successful in the market is the flexibility to integrate with the existing industrial products and control the machinery through interaction human-machine interface through BLE. Additionally, the hardware is designed to reduce time to market for faster prototyping. Adopting Arduino hardware gives the developers many ready-to-use software libraries that make it easier to interact with sensors and actuators.

What is Arduino Portenta Machine Control?

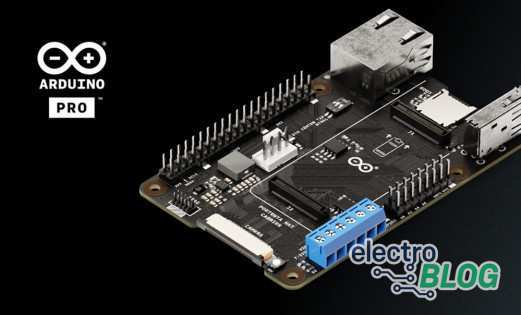

Arduino Portenta Machine Control is an industrial-grade, low-power control unit to drive equipment and machinery. The hardware comes with the STMicroelectronics’ STM32H747XI dual-core Cortex-M7+M4 Arm MCU, the same as the one employed in the existing Arduino Pro Portenta H7 board. With a dual-core processor, the processor does not require any external cooling for heavy workloads. This powerful processor allows the user to connect external human-machine interfaces, including displays, touch panels, keyboards, and joysticks.

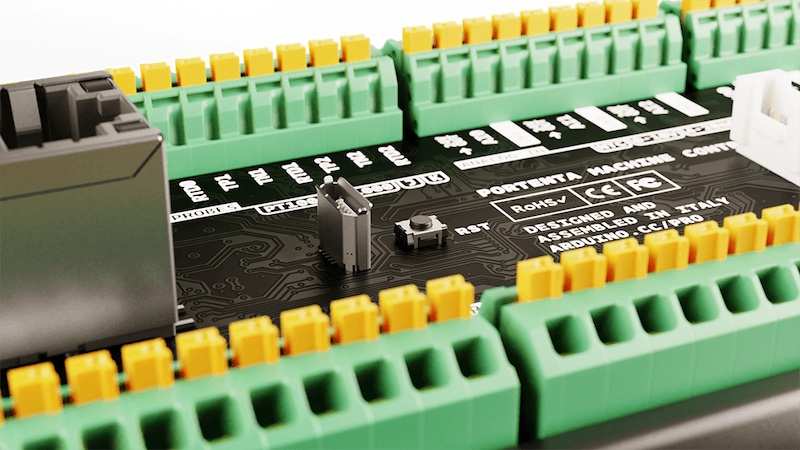

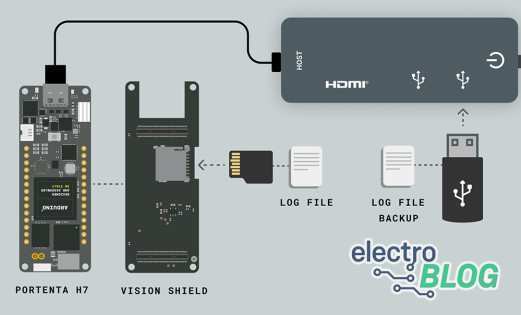

The board offers established wireless connectivity through Wi-Fi and Bluetooth Low Energy for remote control of industrial equipment. Other network connectivity includes the ethernet and USB connection. Some of the tools that can be used to program the hardware are Arduino IDE, Arduino CLI, IoT Cloud, and Web Editor. With the same microcontroller, the board is compatible with Arduino Portenta H7.

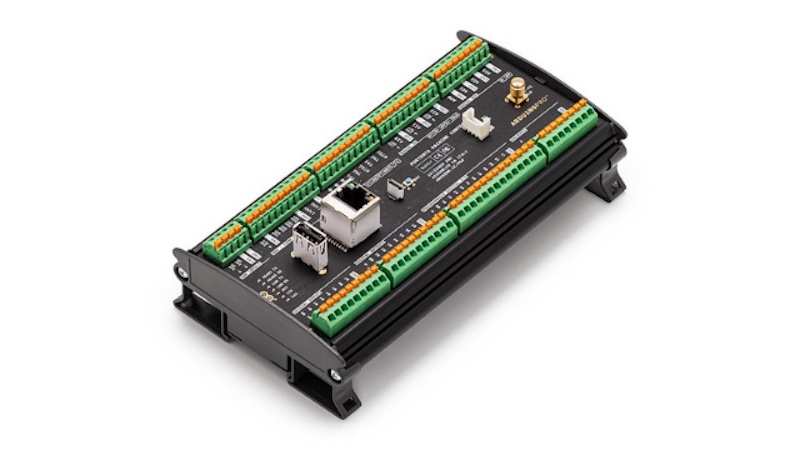

Featuring several input-output analog and digital pins enables the utilization of high-power relays, sample analog signals, and measuring temperature with different probes. Each input-output pin can be controlled separately, giving the operator the flexibility to tailor according to requirements. For industry standards, the board supports RS485 and CAN-BUS communication protocols.

Arduino Portenta Machine Control Specifications

Let's take a look at the specifications of Arduino Portenta Machine Control:

- Microcontroller: Portenta H7 Core

- Processor: STM32H747XI dual-core Cortex-M7+M4 processor with Cortex M7 running at 480 MHz and a Cortex M4 running at 240 MHz.

- Memory: 8MB SDRAM

- Storage: 16 MB onboard Flash memory

- Wireless communication: BLE and Wi-Fi

- Network connectivity: Ethernet and USB programming port

- Communication Protocol: CAN-BUS and Programmable series ports 232, 422, 485

- Programmable IOs: 12

- Power: 24V DC

- Dimension: 90x170x50 mm

- Weight: 186 g

- Operating Temperature: -40° C to +85° C

What can you do with Arduino Portenta Machine Control?

Looking at all the Arduino Portenta Machine Control board’s specifications, it has become one of the most exciting pieces of hardware in the market for fast prototyping in industrial automation use cases. The ability to remote control industrial equipment through the Cloud gives it an edge over other hardware. Along with this, the AI capabilities offered by the Portenta H7 core broadens the offerings and adoption of the carrier board.

Also, with the wide range of support through Arduino libraries, including the Wi-Fi and BLE for wireless connectivity. The Wi-Fi library is designed to use the Murata 1DX module that allows the user to connect the carrier board to the Internet. For example, the carrier board can be integrated with these types of equipment: electric oven, mixer, tempering machine, washers & dryers, and many more.

As the name suggests, the Arduino Portenta Machine Control carrier board enables industry-standard soft-PLC control. It gives the flexibility to connect a wide range of external sensors and actuators with isolated digital I/O, 4-20mA compatible analog I/O, three configurable temperature channels, and a dedicated I2C connector.

Final thoughts on Arduino Portenta Machine Control

Overall, the board looks interesting for those looking to test out some industrial automation projects, and if required, can contact Arduino for commercial purposes. But in general, it depends on the type of project coming to Industry 4.0 as a few of the IOs and additional interfaces can be a hurdle in space constraints and power limitations. Even though with the dual-core architecture, no external cooling is required, finally, it all depends on the type of application and the workload.

The Arduino Portenta Machine Control carrier board makes a giant leap in the Arduino Pro lineup with all the onboard features. The board is designed to serve and improve customer experience with the manufacturing industry through performing predictive maintenance and supporting customers remotely. Arduino claims the Pro products help many corporate users and enhance the manufacturing processes and products.

Have you worked on any of Arduino Pro’s existing boards before? If so, what was your experience like with them as an adopter? Let us know in the comments below!

Leave your feedback...