Harnessing Flexibility: The Flexduino Arduino Uno Clone

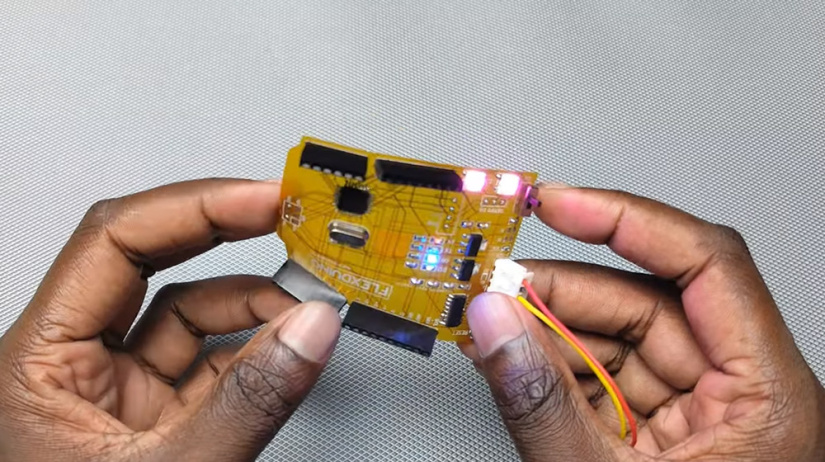

The Flexduino is a fascinating innovation in the world of Arduino Uno clones, setting itself apart with the use of a flexible PCB. This unique design from Edison Science Corner not only provides flexibility in the literal sense but also opens up a range of new possibilities for makers. Whether you're exploring wearable technology or other projects where traditional rigid PCBs fall short, the Flexduino offers a novel solution.

Watch Ian talk about the Flexduino, an Arduino Uno Clone with a Flexible PCB in this episode of The Electromaker Show

Design and Features of the Flexduino

The standout feature of the Flexduino is its utilization of flexible PCB technology. Unlike traditional rigid PCBs, the flexible nature of this board offers enhanced durability and versatility, especially in applications such as wearable electronics and other projects where adaptability is key. This flexibility not only allows the board to fit into unconventional spaces but also provides resilience against physical stress that could damage a standard PCB.

Additionally, the Flexduino integrates addressable LEDs directly onto the board, further expanding its utility in various projects. However, one of the design challenges posed by the flexible PCB is the absence of a ground plane. This limitation necessitated the manual routing of the ground around the board, a workaround that, while effective, adds a layer of complexity to the design process.

Potential Applications and Limitations

The Flexduino is particularly promising in the field of wearable technology. Its flexible PCB allows it to conform to non-traditional shapes and spaces, making it ideal for integration into clothing, accessories, and other wearables where a rigid board would be impractical. This flexibility could also benefit other projects that require a board to fit into compact or oddly shaped enclosures.

However, the innovative design of the Flexduino does come with its own set of challenges. The absence of a ground plane on the flexible PCB required manual routing, which can complicate the design and assembly process. Additionally, the long-term performance of flexible PCBs under varying environmental conditions, such as extreme temperatures and humidity, remains an area that requires further exploration and testing.

Did you enjoy this article?

Make sure you subscribe to The Electromaker Show for similar content and subscribe to our monthly newsletter!

Leave your feedback...