Making Circuit Boards WITHOUT Solder

PCB prototyping has long been a challenge, but innovative solutions are emerging. Steven Hawes, a well-known figure in the maker community, has been on a quest to develop an affordable, open-source pick and place machine. His YouTube channel serves as a treasure trove for PCB enthusiasts, offering practical insights into DIY manufacturing processes. Steven’s work is opening doors for small-scale PCB production, helping makers build their own prototypes without the need for expensive industrial equipment.

Watch Ian talk about a Solder Free PCB prototyping in this episode of The Electromaker Show

Exploring Affordable PCB Manufacturing

For many makers, the cost and complexity of PCB manufacturing have been major obstacles. Steven’s YouTube journey has been an inspiration for those interested in affordable PCB prototyping. His open-source approach offers practical solutions for small businesses and hobbyists alike. At events like Electronica and Embedded World, Steven showcased his pick and place machine, demonstrating its potential to make PCB manufacturing accessible from home. This open-source innovation could be a game changer for anyone needing low-cost PCB production tools.

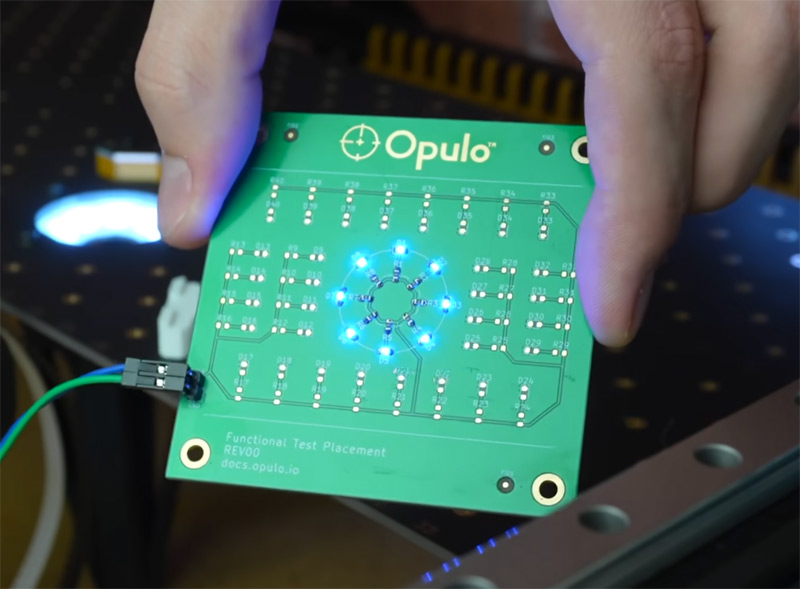

Innovations in Solderless PCB Prototyping

One of Steven's latest innovations is removing the need for solder paste in the PCB prototyping process. In his video, he demonstrates placing components onto a powered board, allowing LEDs to light up immediately after placement—an exciting breakthrough for the community. By bypassing solder paste, this method simplifies the process and makes prototyping more accessible to those without advanced equipment like reflow ovens. This innovation opens new possibilities for affordable and efficient PCB manufacturing at home.

The Future of Open-Source Pick and Place Machines

While Steven’s approach is groundbreaking, it comes with its challenges. As he explains, the current methods for solderless PCB prototyping may not offer the same robustness as traditional techniques. Components can be dislodged more easily. However, Steven is already exploring ways to improve this process, including developing a cost-effective adhesive. This evolution could make PCB prototyping even more accessible to beginners and small businesses. It’s an exciting time for makers looking to experiment with custom PCB designs.

Did you enjoy this article?

Make sure you subscribe to The Electromaker Show for similar content and subscribe to our monthly newsletter!

Leave your feedback...